He 18 June 2025, A customer from India requested the purchase of a lithium battery recycling machine. “We have a waste battery treatment plant and plan to upgrade it to a recycling system with full material recovery. The planned production capacity is 10 tons daily. Please, Send your budget and process outline by email”. According to the requirements, Finally we recommend a mechanical lithium battery recycling line from 1000 kg/h, including crushing systems, trituration, screening and separation, with a total investment of 250.000 dollars. This solution adapts to the industrial energy conditions of India, to low labor costs and growing demand for green battery disposal technology.

What method is suitable for recycling 10 tons per day of lithium batteries?

The Indian customer needed a lithium battery recycling line with a capacity of 10 tons daily. Therefore, for lithium battery recycling equipment, We recommend choosing between the mechanical recycling system or the pyrolytic recycling system. The first offers advantages such as a lower investment cost, easy installation, high separation rate (higher than 95%) and respect for the environment. The second is a better option for those who prefer a more complete recovery from Metals valuable, with stable performance, less manual operation and a high level of automation. Finally, This client chose the mechanical method because of its profitability, flexibility in small-scale operations and compliance with India's strict environmental policies.

|

Method |

Capacity (kg/h) | Power (kW) | Recycling Rate | Cost (USD) |

|---|---|---|---|---|

|

Mechanical Method |

500–1000 | 65–120 | 90–95% |

$150,000-$230,000 |

| Pyrolytic Method | 500–1000 | 65–120 | 92–98% |

$180,000-$280,000 |

How much does a lithium battery recycling plant cost? 10 t/d? Is it within the $250,000?

Generally, for a lithium battery disposal line $250,000, We recommend purchasing a mechanical machine to recycle lithium batteries.. Since the Indian customer already has waste battery treatment facilities and plans to modernize them, These usually include lithium battery recycling equipment such as the following.

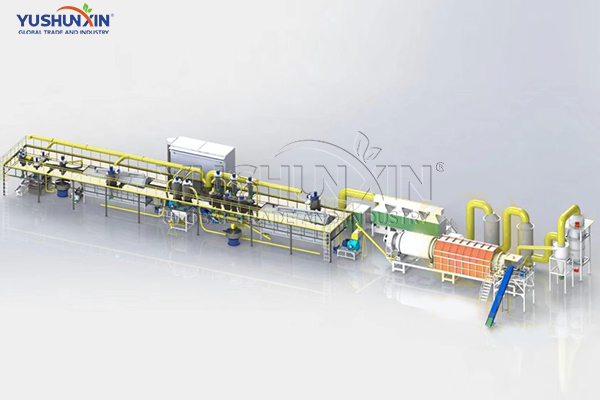

Consists of belt conveyor, single shaft crusher, externally heated carbonization furnace, bucket elevator, deflector separator, wind transporter, drum dedusting machine, hammer mill, drum magnetic separator, turbine mill, circular vibrating screen, air flow sieve, pulse dust collector, quantitative material receiving box.

| Equipment | Capacity (kg/h) | Power (kW) | Quote (USD) |

| Belt conveyor | — | 3 | $9,000 |

| Single shaft shredder | 1000 | 55 | $32,000 |

| Externally heated carbonization furnace | 1000 | 75 | $58,000 |

| Bucket elevator | — | 3 | $5,000 |

| Baffle separator | 1000 | 4 | $8,500 |

| Wind conveyor | — | 7.5 | $8,000 |

| Drum de-powdering machine | 1000 | 11 | $10,000 |

| Hammer mill | 1000 | 22 | $15,500 |

| Drum magnetic separator | — | 7.5 | $9,000 |

| Turbine mill | 1000 | 18.5 | $12,000 |

| Circular vibrating screener | 1000 | 5.5 | $9,500 |

| Airflow screener | 1000 | 11 | $11,000 |

| Pulse dust collector | cyclone + pulse | 7.5 | $12,000 |

| Quantitative material receiving box | — | — | $6,500 |

| PLC control system | — | — | $6,800 |

| Total (EXW) | $211,500 |

What area is required for a lithium battery recycling line? 10 t/d?

Besides, Indian customer asked about the area required for a lithium battery recycling line 10 t/d. You want to know if it is possible to install it in a factory 48 m long and 20 m wide. The answer is yes. In general, All conveyor belts of mechanical lithium battery recycling line are designed with an inclination of 15 degrees. The total height of the line should be approximately 7 m, which means both width and length are suitable. In this case, YUSHUNXIN will offer you a customized lithium battery recycling solution based on your factory layout.

ContentHide