Vibratory separator

Ability – 100-2500kg/h

Precio – $800 – $3.000

Output – 40-100mm

Material – Q235b,stainless steel

Classification rate – 99%

Application – Electronic waste, Metals, madera, paper, etc.

Global service

Service all day

Better guaranteed prices

Accept all credit cards

In the recycling process of Electronic waste, after crushers, Additional refining processing is required. The vibrating zaranda are one of the best options. The vibratory separator can screen and classify better powder and granular materials. This can better achieve the recovery of valuable materials in electronic waste and effectively manage toxic and harmful substances that contain.

A. 2 Types of vibratory separators

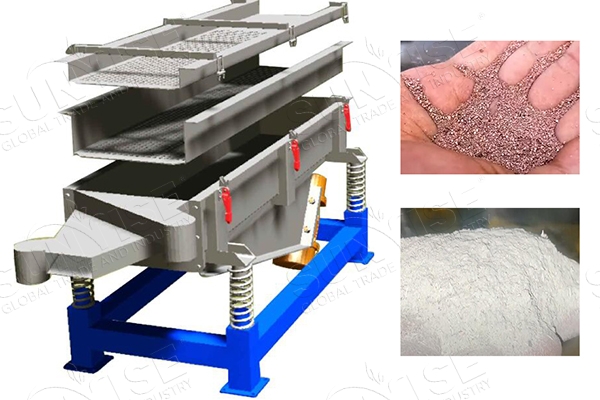

The linear vibratory screens chribe mainly materials with fine particles, Specific Specific Gravity and Low Hardness. Vibration engines on both sides serve as a source of vibration, which makes the material thrown on the screen and advance in a straight line at the same time.

The material enters the power supply port evenly from the feeder, and produces various sizes of screens through the multicapa screen. The upper material and the lower material are discharged from their respective outputs.

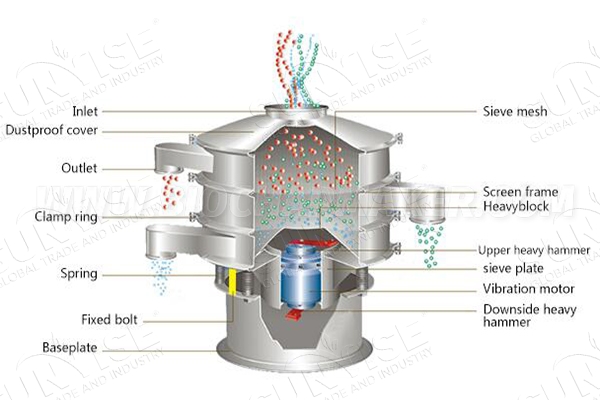

The vibratory circular zaranda chriba mainly materials with heavy specific gravity, Large particles and high hardness. The engine drives the eccentric block of the exciter to turn at high speed through the Trapezoidal Correa.

The generated centrifugal inertia force makes the entire box of the screen viber with a circular movement. The materials are rolled and separate continuously on the surface of the screen, which reduces the blockade of the holes.

At the same time, Through the sieve holes are discharged small particles that meet the particle size requirements. Large particles remain on the screen surface and continue moving up until they are finally discharged.

Of the. What is the design of the vibratory separator?

Linear vibratory screen: The main material is q235b. It is characterized by corrosion resistant and easy to clean. The double -layer screen material is SS304. The upper screen hole size is 10 tights, and the lower screen hole size is 120 tights. The screen can be customized.

Circular vibratory screen: The main material is also Q235B to guarantee structural resistance and corrosion resistance and wear resistance.

Linear vibratory screen: It usually includes main components such as screening box, Criba mesh, Vibration motor, shock absorber, engine base, Download port and food port. The screening box is usually formed by several layers of screens with different mesh sizes, forming a multicapa screening structure.

Circular vibratory screen: mainly includes screening box, Criba mesh, motor, vibrator, Support spring and food and download device.

Three. What are the characteristics of the two vibratory zarandas?

Linear vibratory screen: The inclination angle is small during installation, which facilitates process design.

Circular vibratory screen: The angle of inclination when installed is relatively large, generally between 15 and 20 °, to improve the resistance to the launch of materials on the surface of the screen and improve the efficiency of the screening.

Linear vibratory screen: The surface of the screen is generally a flat or slightly curved rectangular structure. Generally, It is designed as a multi -layer pile, With the opening of the screen of each layer decreasing to achieve a step -by screen.

Circular vibratory screen: The form of the surface of the screen is mainly circular or oval, And the two sides of the screen of the screen are usually designed in a style of “V -shaped expansion”. It is beneficial for the rapid dispersion and screening of materials. It can also be designed in a multi -layer structure.

Four. Prices of the two most popular vibratory screenings

Below are some price parameters that is one of its biggest concerns when buying a vibratory screen. The price of a linear vibratory screen with a capacity of 100 kg/h-200kg/h is from 1000 a 3000 dollars. The price of a circular vibratory screen with a capacity of 150 kg/h-2500kg/h is from 800 a 3000 dollars. We invite you to contact us to obtain the price parameters that are more suitable for your situation.

These two vibratory screens have very good screening capabilities and we recommend that you choose their needs. At the same time, We also provide other electronic waste recycling equipment, including double axis crushers, hammer crushers, Specific gravity separators, magnetic separators, Optical separators, etc. We hope to become your partner, Welcome to contact us for more details.