Magnetic separator

Ability – 1-5 t/h

Precio – $1.000 – $3.000

Classification rate – 99%

Material – Q235b,stainless steel

Warranty – 1 year

Application – Electronic waste, Metals, etc.

Global service

Service all day

Better guaranteed prices

Accept all credit cards

SI choose equipment to recycle Lithium batteries used, Then you can consider a magnetic separator. As a piece Team key For electronic waste recycling. Magnetic separators can separate and recycle used lithium batteries, Then you can consider a magnetic separator. As a piece Magnetic materials efficiently. You can also help you get more economic benefits while improving the resource recycling rate, reduces environmental pollution and promotes sustainable development.

A. What is a magnetic separator?

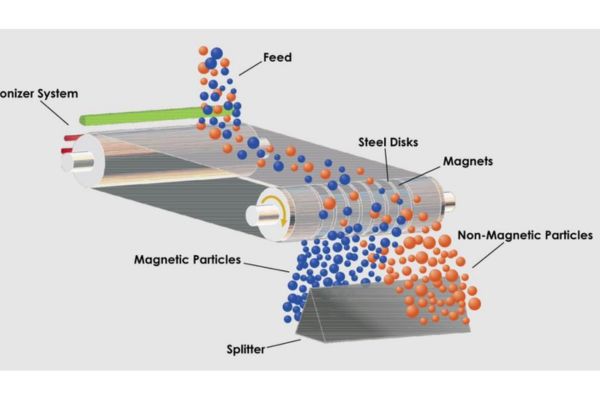

The magnetic separation equipment is a central team widely used in the recovery of resources and mineral processing. It is a device that uses a strong magnetic field to achieve an effective separation of magnetic and non -magnetic particles in mixed materials. In the Electronic waste recycling equipment, He is mainly responsible for precisely extracting magnetic metal elements such as iron (Fe), nickel (In) and cobalt (Co) of the complex waste mixture and accurately separate non -magnetic materials.

Of the. How does the magnetic separator work?

In it Lithium battery recycling process of waste. After the pretreatment steps, Like crushing and spraying. The materials will form fine particles with a uniform particle size.

Then, Crushed and separated materials are sent to the conveyor belt.

Other non -magnetic materials are transported to the following process by magnetic separation. In this way the objective of automatic iron elimination is achieved.

Three. What are the advantages of the magnetic separator?

Due to rapid and direct magnetic force, The magnetic separation process is not affected by changes in moisture of the material and particle size, which guarantees high efficiency separation performance. The magnetic separator can effectively identify and effectively capture the magnetic components of the materials in a high -speed movement tape. In this way the magnetic material is separated.

These separators can work continuously, which guarantees a constant and uninterrupted separation process. They are designed to support the harsh conditions of industrial environments and can handle large volumes of frequent maintenance material or inactivity time.

Magnetic separators on the band improve safety by eliminating potentially dangerous ferrous materials from material flow. This helps protect downstream equipment and avoids damage caused by metal pollution, which reduces the risk of accidents and breakdowns.

Compared to other types of separation methods, Magnetic separation technology does not require the use of chemicals and, therefore, is more environmentally respectful and harmless. Magnetic separators have low operating costs and energy consumption. Its long -term use can significantly reduce the production costs of companies and meet the requirements of the ecological and sustainable development of the modern industry.

Four. The price of the magnetic separator

The price of our magnetic separation machine with a 1-5T/h output is approximately $1000-$3000. If you have a deeper understanding, You can contact us, We will give you a detailed and professional response.

Cinco. Why choose us as a machine manufacturer?

EThe magnetic separator in electronic waste recycling is an important tool to improve the resource recovery rate, With many advantages, as to efficient separation, the reuse of resources and respect for the environment.

The correct choice of a magnetic separation device can maximize the recovery and reuse of magnetic materials in electronic waste, Perform resources recycling and contribute to environmental protection and sustainable development.

At the same time, We can also provide some other related equipment: double axis crusher, spray, Circular vibratory screen, specific gravity separator, etc.