Lithium battery recycling process

Ability – 500-2000 kg/h

Precio – $15.000 – $35.000

Classification rate – 99%

Material – Q235b,stainless steel

Warranty – 1 year

Application – Electronic waste, Metals, etc.

Global service

Service all day

Better guaranteed prices

Accept all credit cards

Con the development of new energy technologies, las Lithium batteries are widely used. Y how to reuse them Once its life cycle has ended, it has become the center of attention.

He lithium battery recycling equipment can recycle positive electrode materials, negative electrode materials, separators and other materials in lithium batteries efficiently and environmentally in the lithium cell recycling process.

A. Why recycle lithium batteries?

The problem of lithium battery contamination cannot be ignored. Lithium batteries contain heavy metals(mercurio, lead, cadmium). If discarded lithium batteries are not recycled and processed properly, The degree of environmental pollution they cause is quite serious.. Can leach into soil and water. Metals are highly toxic and can cause irreversible damage to flora and fauna..

Recycling lithium batteries can recover the metal and reuse it in new products. Lithium battery recycling process helps reduce the need to extract new metals from the earth. Therefore, Recycling batteries protects the environment and saves resources. At the same time, we gain economically from recycling.

Of the. What is the lithium battery recycling process like??

1. Discharge

Before entering the lithium battery recycling process, If there is still battery energy, It is necessary to download it. If discharge treatment is not performed, It is easy for sudden explosions and other phenomena to occur, which will have a great impact on the production of equipment.. The integrated download machine can download very well.

2. Lake

Perform primary crushing and secondary crushing of lithium batteries. Crush lithium batteries to ideal size.

3. Detection

Use screening equipment to screen the crushed mixture to separate and collect valuable metals, etc.

Three. What are the main equipment included in the lithium battery recycling process??

- Double axis crusher

By rotating two shines of blades with blades, First the circuit plate is crushed.

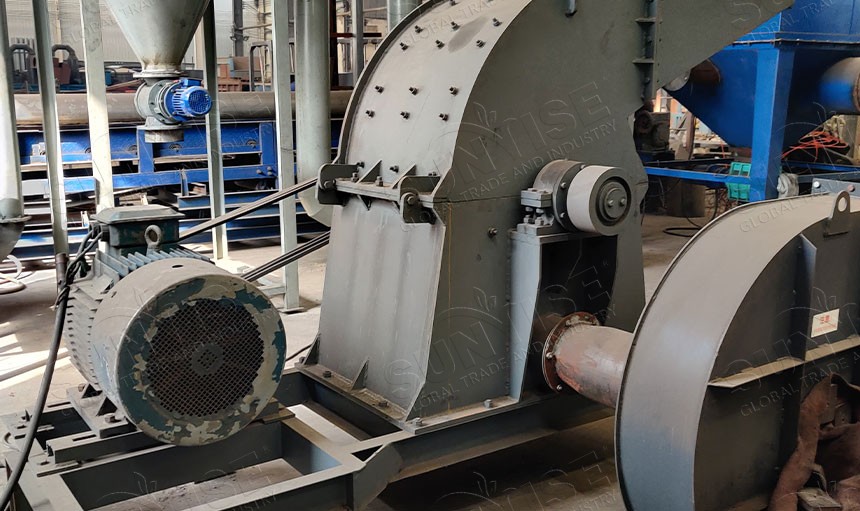

- Hammer crusher

The internal structure is a hook blade and a hammer head, that crush the materials under the high speed rotation of the main axis.

- Vibratory separator

Linear Air Separation Vibrating Screen and Circular Vibrating Screen

- Magnetic separator

The materials are separated according to whether they are magnetic.

Four. Advantages of the lithium battery recycling process

Lithium battery recycling uses physical sorting.

Physical separation is suitable for large-scale lithium battery recycling. And can handle many types of batteries and other electronic waste. Automated and mechanized processes meet the high efficiency needs of industrial production.

Compared to wet process, The physical sorting process generally produces no harmful chemical waste and causes less pollution to the environment.

Physical sorting does not require the purchase of chemical reagents or energy and is less expensive than wet processes. Physical sorting requires an investment in equipment at the initial stage and has lower operating costs in the long term.

Cinco. Price of equipment in the lithium battery recycling process.

The processing capacity of lithium battery recycling equipment is 500-2000 kg/h, which is also affected by other factors. Therefore, the price of the equipment is different. Detailed quotes are available by contacting us.

EThe lithium battery recycling process is very ecological and efficient. Lithium batteries can be recycled and processed to the greatest extent possible.

Besides, we offer Recycling equipment for printed plates, solar panel recycling equipment, pyrolysis machine for recycling photovoltaic panels y etc..