Due to the increasing demand for lithium battery recycling and the need for electronic waste treatment, More and more companies invest in the processing of lithium batteries. For example, he 25 September of 2024, A customer from Mexico asked how to install an electronic waste disposal line. 500 kg/h for lithium battery processing. This client told us “… complete line, from the reception of used lithium batteries to the extraction of precious metals. With a capacity of 500 kg/h… send me the design, price…” The following are the specific details of our communication in this case:

What is the basic equipment of a lithium battery recycling plant?

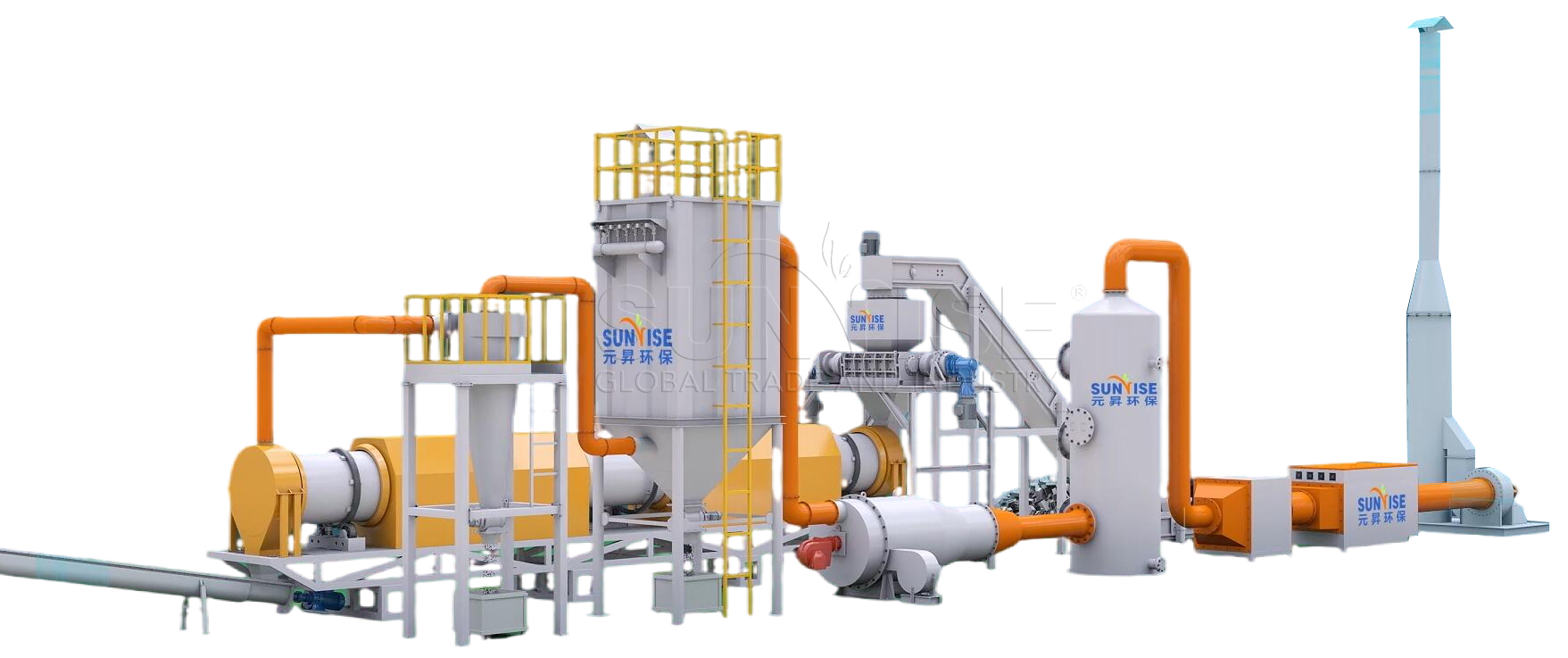

This Mexican customer wanted to buy a complete lithium battery recycling line, from shredding waste lithium batteries to metal collection, with a capacity of 500 kg/h. Then, during subsequent communications, asked us what equipment is needed in a complete lithium battery recycling production line in detail. In general, contains the following machines:

What is the design of a lithium battery recycling plant? 500 kg/h?

When you want to install a lithium battery disposal plant, The factory area are also two aspects that must be taken into account.. In general, The entire lithium battery processing area is divided into three parts:

How much does it cost to install a lithium battery disposal plant? 500 kg/h in Mexico?

Finally, The client from Mexico requested a quote for a lithium battery recycling production line with a capacity of 500 kg/h. Due to the use of Electronic waste recycling equipment quality, the price is between 15 000 y 36 000 dollars. Can I install a lithium battery processing plant 500 kg/h in Mexico at a lower cost? The answer is yes. You can only buy some necessary recycling machines. And we will adjust the equipment according to your actual situation. Therefore, has a cheaper price.