He 16 February 2025, A customer from India requested the installation of a lithium battery recycling plant. I needed a mechanical lithium battery recycling machine first.. This machine can achieve a recycling rate higher than 90 %. To do this, We recommend the mechanical lithium battery disposal line with a capacity of 500 kg/h. Next, details of our communication in this case are detailed:

What is the design of a lithium battery recycling plant? 500 kg/h?

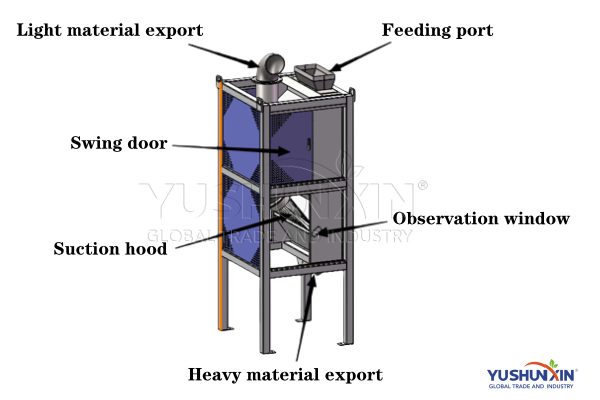

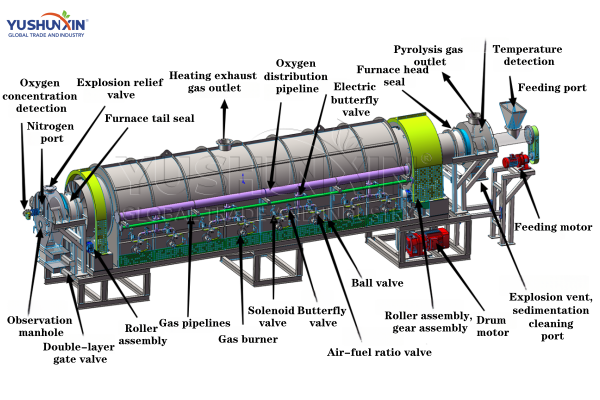

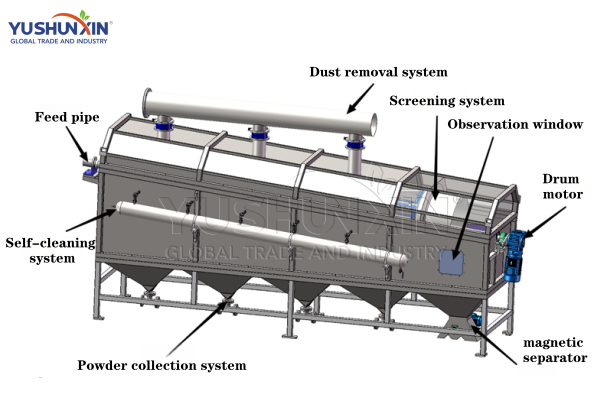

India's lithium battery recycler required a mechanical method. Therefore, The design of a standard lithium battery disposal plant 500 kg/h adopts corresponding machinery. The main flow of the lithium battery recycling process consists of 14 machines: conveyor belt, single shaft crusher, carbonization oven with external heating, bucket elevator, deflector separator, wind transporter, drum deduster, hammer mill, drum magnetic separator, turbine mill, Circular vibratory screen, air flow sieve, pulse dust collector and quantitative material receiving box. In this configuration,

Can the drum dedusting machine separate the black powder into 120 mesh?

Yeah. The mesh number of drum dedusting machine is 120 tights.

How about dust reduction in black powder separation?

On the one hand, drum dedusting machine works in a closed drum, which greatly prevents the dispersion of black powder. On the other hand, It has a professional dust collection system for black powder separation. Includes a cyclone collector and a pulsed dust collector.

How long does it take to recover the investment in a lithium battery recycling plant? 500 kg/h?

When estimating the construction time of a lithium battery recycling plant, it is necessary to know the cost of the equipment. To purchase it at Yushunxin, investment for a lithium battery recycling plant 500 kg/h is approximately $140,600 EXW. The details are as follows:

| Equipment | Capacity (kg/h) | Power (kW) | Quantity | Quote (USD) |

| Belt conveyor | — | 2.2 | 3 | $4,500 |

| Single shaft shredder | 500 | 22 | 1 | $18,000 |

| Externally heated carbonization furnace | 500 | 45 | 1 | $28,000 |

| Bucket elevator | — | 2.2 | 2 | $5,600 |

| Baffle separator | 500 | 4 | 1 | $6,800 |

| Wind conveyor | — | 3 | 2 | $4,800 |

| Drum de-powdering machine | 500 | 5.5 | 1 | $7,500 |

| Hammer mill | 500 | 15 | 1 | $9,800 |

| Drum magnetic separator | — | 3 | 1 | $6,200 |

| Turbine mill | 500 | 18.5 | 1 | $12,000 |

| Circular vibrating screener | 500 | 4 | 1 | $7,800 |

| Airflow screener | 500 | 5.5 | 1 | $8,600 |

| Pulse dust collector | — | 7.5 | 2 | $9,000 |

| Quantitative material receiving box | — | 2.2 | 1 | $5,200 |

| PLC control system | — | — | 1 | $6,800 |

| Total (EXW) | $140,600 |

Using locally collected waste lithium batteries, The production cost remains around 400-500 dollars per ton. The sale price on the market for recovered materials, like copper, aluminum, graphite and lithium compounds, average between 800 y 1000 dollars per ton, resulting in a profit margin of between 300 y 500 dollars per ton. At full capacity, a lithium battery recycling plant 500 kg/h can generate an annual net profit of between 2,5 y 4,5 Millions of dollars. However, during operation, There are also ongoing factory rental costs., electricity, labor and equipment maintenance. Even so, The payback period is usually one to two years., what makes the lithium battery recycling plant not only in an ecological solution, but also in a highly profitable and sustainable investment project.

The above details our communication with the customer regarding the lithium battery recycling plant of 500 kg/h. Besides, we offer you solar panel recycling plants, tire pyrolysis plants y lithium battery disposal plans 1000 kg/h, inter alia. Get your own e-waste recycling plan!!