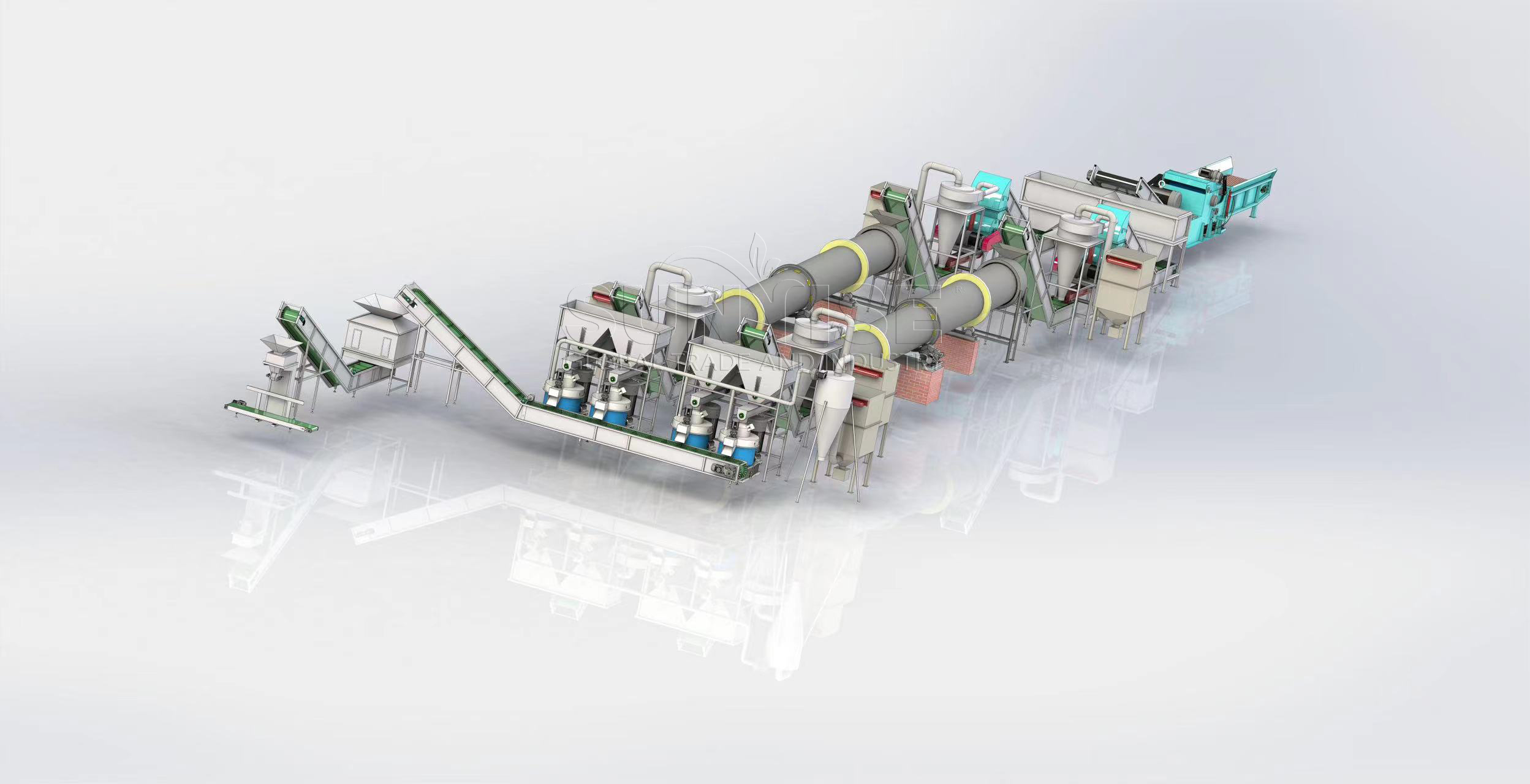

A recycling production line with a capacity designed to process 200 photovoltaic panels per hour not only reflects an environmentally responsible attitude, but also demonstrates a double technical and economic benefit. Production lines usually include the following main equipment:

Carbonization equipment model.

Pretreatment system: first, PV panels need to be cut or broken to remove non-PV components, such as frames and junction boxes. This process uses automated cutters or shredders to ensure safe and efficient separation of materials.

Sorting device: Separates different materials such as metal, glass and plastic by magnetic separation, eddy current separation, electrostatic separation and other physical methods. This step is essential to improve the purity of the material for subsequent recycling..

pyrolysis oven: to recycle silicon wafers into photovoltaic panels, pyrolysis oven decomposes organic matter, like the movie EVA, at high temperature to separate silicon wafers. This process also reduces the emission of harmful substances.

Automated conveyor system: Automated conveyor belt running along the entire production line ensures smooth transition of materials between various work sections, improving overall operational efficiency and safety.

Data monitoring and control system: Intelligent data collection and analysis system monitors production status in real time, optimizes process parameters and ensures stable production line operation and optimal performance.

This production line can not only effectively recycle valuable materials into photovoltaic panels, like silicon, plata, copper and glass, but is also committed to minimizing waste generation and achieving resource recycling., which is a concrete practice of the green manufacturing concept.

Leave A Comment