Because the sale of precious metals can generate more profits, Most e-waste managers are prone to recycling precious metals and other materials from e-waste. Of course, including the lithium battery recycling, circuit board management and removal of solar panels, etc. Then, to recycle high quality precious metals, it is necessary to purchase a suitable e-waste separator machine. As of the last date on 2024, We found that there are five types of e-waste separators that sell very well among e-waste managers..

No.1 Electrostatic separator using high voltage power supply

For metal and non-metal recycling projects, Most e-waste managers choose our high voltage electrostatic separator. Because? There are four reasons:

| Model | Dimension (mm) | Drum He. (mm) | Speed(rpm) | Power(kw) | Sorting Voltage(V) | Particle Size(mm) |

| YS-1000 | 1800*1350*3500 | 320 | 30-900 | 3.6 | 20-60000 | 0.01-4 |

| YS-1500 | 2300*1350*3500 | 320 | 30-900 | 5.5 | 20-70000 | 0.01-4 |

| YS-1800 | 2650*1350*3600 | 320 | 30-900 | 7.5 | 20-80000 | 0.01-4 |

Nº2 Magnetic separator with wet and dry type drum

He magnetic separator can be divided into wet magnetic separator and dry magnetic separator. Wet magnetic separator is the commonly used separator in mineral processing plants, which is applied to separate strong magnetic minerals. And the magnetic separator can separate magnetite, limonite, hematite, manganese siderite ore, manifest, wolframita, mineral, metallurgical manganese ore, manganese oxide, iron ore, kaolin, rare earth mining, etc. Then, The magnetic separation process is carried out by magnetic and mechanical force on the particles in the magnetic field. Different magnetic mineral grains will move along a different path, thus classifying into two or more separate mineral processing products. And what are the benefits of magnetic separator?

| Model | Diameter (mm) | Length (mm) | Magnetic intensity of cylinder surface (Qa) | Separating Particle Size (mm) | Capacity (t/h) | Motor power (kw) |

| YS-69 | 600 | 900 | 450 | 0-0.2 | 8-15 | 1.5 |

| YS-612 | 600 | 1200 | 450 | 0-0.2 | 15-25 | 1.5 |

| YS-618 | 600 | 1800 | 450 | 0-0.2 | 15-30 | 2.2 |

| YS-712 | 750 | 1200 | 550 | 0-0.2 | 12-30 | 3 |

| YS-718 | 750 | 1800 | 500 | 0-0.15 | 20-45 | 3 |

| YS-918 | 900 | 1200 | 550 | 0-0.2 | 45-80 | 4 |

| YS-924 | 900 | 2400 | 500 | 0-0.15 | 60-100 | 4 |

Nº3 Gravity separator for screening heavy and light materials

He severity separator works on the fluidized bed principle. The material is fed onto an oscillating sieve platform. Through air pressure and platform oscillation, the material fluidizes and stratifies. The heavy fraction sinks into the platform while the light fraction remains suspended in a fluidized state.. The oscillation of the platform causes the heavy and light fraction to travel on separate paths and be collected separately. According to the previous principle, it is more precise to separate materials of different densities. Therefore, Many customers have given good comments after purchasing our equipment. Besides, can recycle metal from electronic waste at a lower cost.

| Model | Air volume (m3/min) | Vibrating frequency | Screen material | Screen fineness (one) | Power (kw) | External dimension (mm) |

| YS-400 | 805-1677 | 40-200 | Stainless steel spiral weaving | 15-200 | 0.75 | 600*1250*1650 |

| YS-750 | 1688-3517 | 40-200 | Stainless steel spiral weaving | 15-200 | 1.5 | 900*1650*1680 |

| YS-1000 | 2664-5628 | 40-200 | Stainless steel spiral weaving | 15-200 | 3 | 1200*1850*1680 |

Nº4 Vibrating screen of two types

For screening precious metals and other materials of different sizes, especially copper and aluminum, The most popular equipment is linear screens and circular vibrating screens. Because?

Linear vibratory screen

It is composed of a discharge port, a screen, a vibration motor, a spring and a dustproof cover. First of all, The material of this machine is carbon steel or stainless steel 304/316. Then, the screen mesh is made of stainless steel 304 High quality, Screen size can be customized according to customer requirements. Finally, we can add dustproof cover for equipment, design an observation hole and use a quick switch.

| Model | Effective screening area | Granularity size | Deck | Power(kw) | Speed(rpm) | Amplitude(mm) |

| YS-520 | 500*2000 | 0.074-60 | 1-4 | 2*0.75 | 960 | 4-8 |

| YS-840 | 800*4000 | 0.074-60 | 1-4 | 2*1.5 | 960 | 4-8 |

| YS-1030 | 1000*3000 | 0.074-60 | 1-4 | 2*1.9 | 960 | 4-8 |

| YS-1255 | 1200*5500 | 0.074-60 | 1-4 | 2*2.2 | 960 | 4-8 |

| YS-1650 | 1600*5000 | 0.074-60 | 1-4 | 2*3 | 960 | 4-8 |

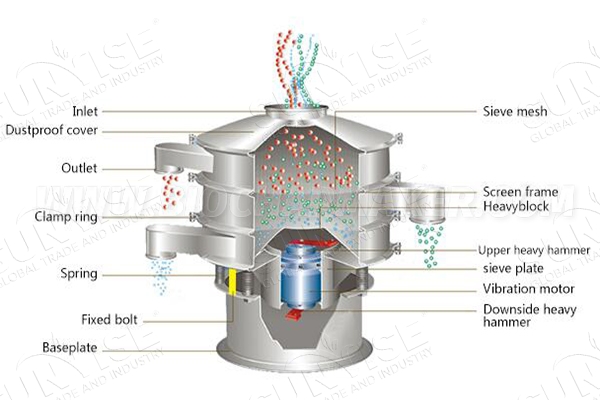

Circular vibratory screen

This machine is a low frequency rotary vibrating screen that imitates artificial agitation. It is an efficient and cost-effective method to classify and separate particles of different sizes.. The benefits of using a rotary vibrating screen include high efficiency, continuous operation, low noise levels and easy maintenance. Besides, can be customized to meet specific material requirements and is capable of separating particles ranging from very fine to coarse.

The above are the 5 best e-waste separators in 2024. Besides, SX can also provide you with many other e-waste processing machines. For example, Lithium battery recycling equipment, circuit board removal machines, solar panel recycling lines and solar panel dismantling machines. If you are interested in them, contact us. We will provide you with high quality e-waste processing machines at an ideal price!!