When planning the solar panel recycling With mechanical methods, There is a fundamental element: The disassembly machine. This is because the photovoltaic panels should first be disassembled before crushing and screening the desired metals. To do this, he 1 April of 2025, A Spanish client had a company dedicated mainly to the disassembly and recycling of wind turbines at the end of its useful life. Now, They are expanding to the solar panel recycling sector and are especially interested in acquiring a machine to disassemble the structures of solar panels. Next, The specific details of our communication are detailed in this case:

What teams can help you disassemble solar panels?

This Spanish client wanted to acquire Machines to disassemble solar panels. To do this, There are two types of machines: Marcos disassembly and glass disassembly.

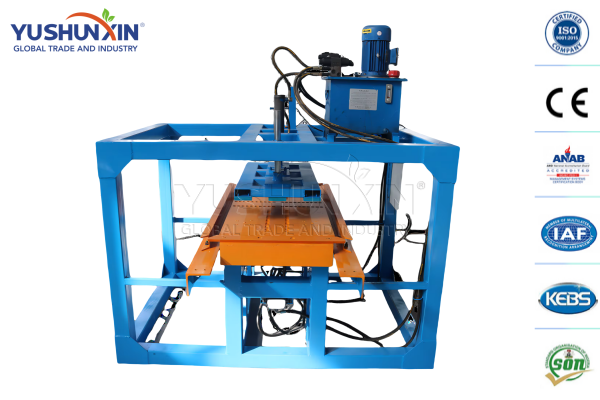

Marcos to remove machine

In general, There are two types of Marcos extraction machines: semi -automatic and totally automatic. Both allow to disassemble marks of solar panels of 1000 kg/h with different efficiency. You can choose the one that best suits your needs.

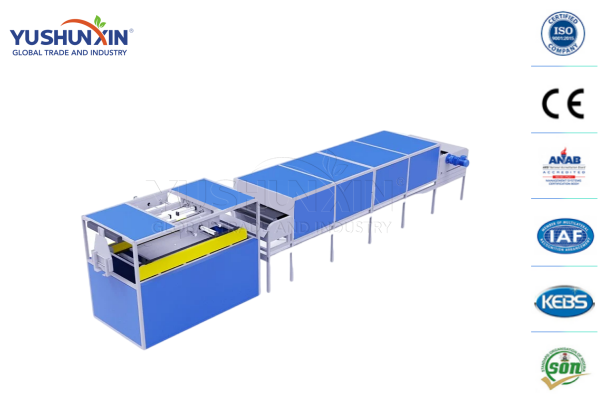

Glass equipment

The glass separating machine for photovoltaic panels is a device specifically designed to process photovoltaic waste panels, especially monochronic silicon glass panels and silicon polycrystalline. This equipment incorporates automation technology for food, automatic download and separation from glass and finished panels. This allows to improve production efficiency and reduce labor costs.

How much does it cost to acquire a solar panel disassembly line?

After informing about solar panel disassembly equipment, This Spanish client wanted to know more about prices. I hoped we could offer you some solar panel disassembly solutions as a reference.