If you want to start a solar panel recycling project, Consult us in Yushnxin! We have mechanical recycling lines of solar panels and pyrolysis plants of photovoltaic panels. These plants meet their recycling needs of solar panels with a capacity to 1 a 2 t/h, For small or large areas, etc. Besides, They allow you to get profits quickly. Contact us now for your business plan Electronic waste recycling!

What is the price of solar panel recycling machines?

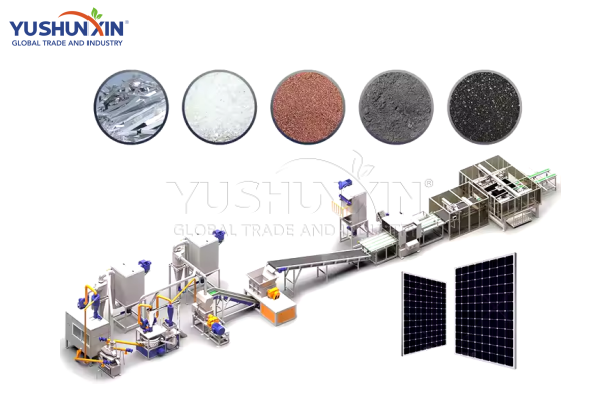

Generally, Photovoltaic panels can be recycled by two methods: mechanical and pyrolysis. Therefore, The electronic waste recycling equipment company YUSHUNXIN Design a mechanical recycling line of solar panels and a pyrolysis plant of photovoltaic panels. Due to the different configurations, The price of solar panel recycling machines is the following:

Cost of the recycling line of mechanical solar panels

Generally, the cost of a Mechanical Recycling of Solar Panels is closely related to your processing capacity and the configuration of your equipment. For small -scale recycling lines with a capacity for 0,5 a 1 t/h, total investment ranges from $100.000-$150.000. A medium -scale line that processes 1 a 3 t/h usually costs between $150.000-$280.000, while large -scale facilities with a capacity for 3 a 5 T/h may require between $280.000-$450.000. En YUSHUNXIN, We design and manufacture complete mechanical recycling systems of solar panels. A complete line includes: Marcos extraction machine, glass extraction equipment, double axis crusher, hammer mill, Vibratory screen, Gravitational separator, electrostatic separator and conveyor belt.

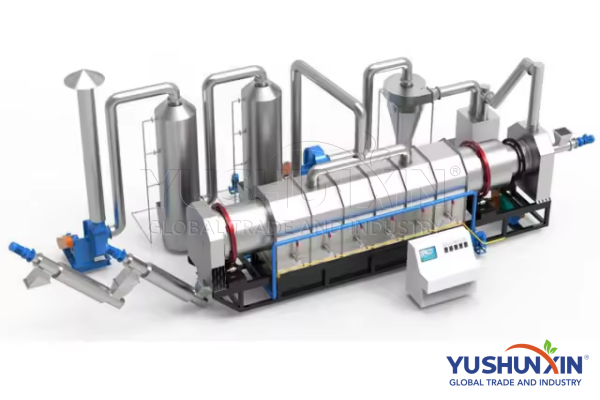

Pyrolysis Plant Budget of photovoltaic panels

If you seek to recycle photovoltaic panels at the end of your useful life through the pyrolysis method, We recommend ours standard recycling solution by pyrolysis. This system is specifically designed to thermally decompose the organic materials of encapsulation of solar panels and separate valuable components such as silicon, Glass and metals. Complete configuration includes a pyrolysis machine, A vibratory screen, A color classifier, a dust collection system and a conveyor belt. Compared to complex lines of mechanical separation, This solution uses less machines, But more specialized, which helps reduce both equipment costs and workshop requirements. As a result, offers a more compact and profitable configuration for investors. Normally, the total budget required for a complete recycling line of solar panels by pyrolysis ranges between $80,000 y $180,000, depending on the capacity and level of automation.

What is the cost of the land to build a photovoltaic panel recycling plant?

In addition to the expense in the purchase of machines for the recycling of solar panels, Much of the cost of a solar panel recycling plant corresponds to the investment in land. In general, This is closely related to two factors: The necessary area for its recycling line of photovoltaic panels and the price of the land in your country. En YUSHUNXIN, We will provide the details of the land occupation for the design of the solar panel recycling plant.

Mechanical Recycling

|

Capacity (T/H) |

Area (㎡) |

|---|---|

|

0.5-1 |

400 |

|

1-1.5 |

600 |

|

1.5-2 |

800 |

Pyrolysis Recycling

|

Capacity (T/H) |

Area (㎡) |

|---|---|

|

0.5-1 |

500 |

|

1-1.5 |

800 |

|

1.5-2 |

1200 |

If you need the cost of the land for install your own solar panel recycling plant, Contact us for more information. Just send us the price or rental of the local land and we will give you the answer after deciding the photovoltaic panel recycling plan.

How much energy does the solar panel recycling machine consume?

Energy consumption of the mechanical recycling machine of solar panels

Mechanical solar panel recycling machines mainly use electricity to boost various processes, Like disassembly, Crushing, screening and separation. Besides, These systems use compressed air during electrostatic separation and dust collection. During equipment operation, Electricity efficiently drives mobile parts and facilitates continuous flow of material through the recycling line. At the same time, Compressed air guarantees an effective separation of materials and maintains a clean work environment through dust elimination. The combination of these types of energy results in a total cost of approximately $7.4 By ton processed solar panels. Therefore, The mechanical recycling process stands out for its low energy consumption and profitability.

| Equipment | Power (kW) | Avg. Consumption (KWH/Ton) | Energy Cost (USD/ton, $0.12/kWh) |

| Frame remover | 7.5 | 5 | $0.6 |

| Glass remover | 7.5 | 6 | $0.7 |

| Double shafts shredder | 22 | 15 | $1.8 |

| Hammer mill | 30 | 20 | $2.4 |

| Vibrating screener | 3 | 2 | $0.2 |

| Gravity separator | 4 | 3 | $0.4 |

| Electrostatic separator | 5 | 4 | $0.5 |

| Belt conveyor (multiple) | 2*4 | 3 | $0.4 |

| Electricity total | — | 58 KWH/Ton | ≈ $7.0/ton |

| Compressed air (to.) | — | 3 KWH/Ton (equivalent) | $0.4 |

Energy consumption of a pyrolysis plant of photovoltaic panels

Instead, Pyrolysis plants of photovoltaic panels use electricity and fuel (Normally natural gas) To complete the recycling process. Electricity is essential for the operation of conveyor belts, screening machines, Classification equipment, Dust collection systems and process controls. On the other hand, Natural gas provides the thermal energy necessary to heat the pyrolysis oven, which allows the decomposition of the panel components at high temperatures. The thermal energy necessary for this operation oscillates between 250 y 350 to intention. With a price of natural gas from some 0,05 dollars per kWh, The cost of fuel alone amounts to some 12-18 dollars per ton. By combining electricity and fuel costs, The total energy cost of the pyrolysis method reaches approximately between 15 y 21 dollars per ton. Therefore, While this method allows you to recover certain materials more exhaustively, It usually entails greater energy consumption and operating costs higher than those of mechanical recycling.

| Equipment | Power (kW) | Avg.Consumption (KWH/Ton) | Electricity Cost (USD/ton) |

| Pyrolysis machine | 20 | 10 | $1.2 |

| Vibrating screener | 3 | 2 | $0.2 |

| Color sorter | 4 | 3 | $0.4 |

| Dust collection system | 5 | 4 | $0.5 |

| Belt conveyor (multiple) | 2*3 | 3 | $0.4 |

| Electricity total | — | 22 KWH/Ton | ≈ $2.7/ton |

What payment method is better when importing a Yushunxin solar panel recycling line?

When importing a Yushunxin solar panel recycling line, It has access to various flexible and safe payment methods. Either telegraphic transfer, letter of credit, documents against payment or documents against acceptance, You can freely choose according to your financial situation.

- 1

In addition to traditional options, Yushunxin also offers DDP service (Delivery with paid rights). If you prefer a process without complications and want to receive the equipment directly at your home, Opting the DDP service will save the discomfort of customs office and logistics. It is ideal for those who import recycling equipment for photovoltaic panels for the first time or lack import experience.

- 2

As for the payment of the Yushunxin solar panel recycling machine, an initial payment of the 50%. He 50% remaining is paid before sending or at the time of delivery, According to the conditions chosen. Besides, Anticipated or total payment can give you additional discounts, With savings of up to a 10% In the total price of its recycling machines of photovoltaic panels. This gives you payment flexibility, In addition to profitability and tranquility.

ContentHide