Currently, Research on recycling used lithium batteries mainly focuses on the recovery of high-value precious metals such as cobalt and lithium. And the copper on the negative electrode of used lithium batteries (content of up to 35 %) It is an important production raw material widely used. Based on the structural characteristics of lithium batteries, We adopt an environmentally friendly physical separation process to achieve efficient separation and recovery of used lithium batteries.

Currently, Research on recycling used lithium batteries mainly focuses on the recovery of high-value precious metals such as cobalt and lithium. And the copper on the negative electrode of used lithium batteries (content of up to 35 %) It is an important production raw material widely used. Based on the structural characteristics of lithium batteries, We adopt an environmentally friendly physical separation process to achieve efficient separation and recovery of used lithium batteries.

What types of batteries can be recycled in lithium battery disposal plant?

To recycle lithium batteries, The first step is battery selection. To do this, There are two aspects you should focus on when choosing lithium batteries to dispose of..

Types of lithium battery recycling (ingredients)

Ways to dispose of lithium batteries

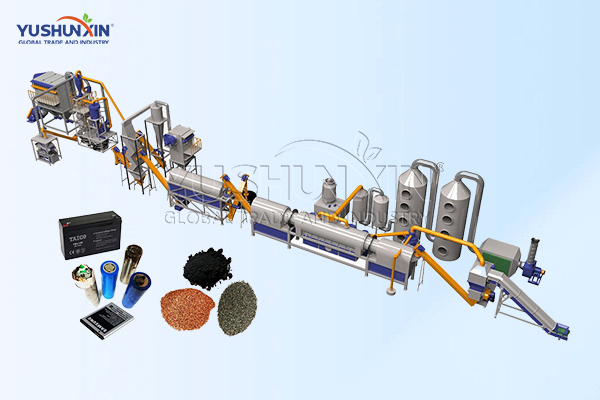

If you plan to recycle lithium batteries, There are three types of battery shapes for reference: bag type battery, block type battery and cylindrical battery.

What types of batteries can be recycled in lithium battery disposal plant?

To recycle lithium batteries, The first step is battery selection. To do this, There are two aspects you should focus on when choosing lithium batteries to dispose of..

Types of lithium battery recycling (ingredients)

Ways to dispose of lithium batteries

If you plan to recycle lithium batteries, There are three types of battery shapes for reference: bag type battery, block type battery and cylindrical battery.

How to recycle lithium battery to get more profit?

If you plan to recycle lithium batteries, which can help you make more profits, Our lithium battery recycling line is an ideal choice for you. It can help you get graphite powder, cobalt acid, lithium, aluminum and copper, etc. quickly and easily. So, What is the design of lithium battery recycling production line? (Tips: The lithium batteries processed at the plant are all discharged)

Double axis crusher

If you want to recycle lithium batteries, The first step is to crush them into small pieces.. First you must shred lithium battery into small pieces to facilitate subsequent shredding. After crushing them, one piece measures 10 cm long and 4 cm wide.

Hammer mill

The finer the lithium battery powder, the better the quality of the final product. Therefore, A suitable shredder is necessary for recycling lithium batteries. In this case, he hammer mill It is an excellent option for you. And we recommend you buy two hammer mills for making lithium battery fine powder. After grinding twice, the length is 3-4 cm and the width is 2 cm.

Air separator

This machine is composed of a linear vibrating screen and a fan. And the airflow separator has two layers of screens: the top screen is mesh 30 and the bottom screen is mesh 120. Besides, you can customize the display for your lithium battery powder.

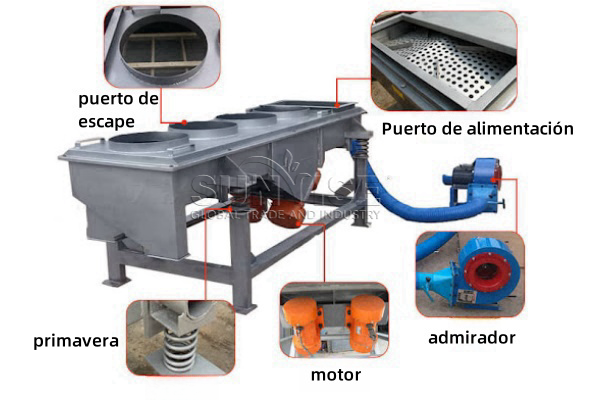

Sorting screen

The screening machine In this step you can use a circular vibrating screen or a linear vibrating screen. Can help you filter out some of the metal from lithium battery waste.

Magnetic separation machine

The magnetic separation conveyor is equipped with a magnetic separation device which can separate magnetic materials (iron layers, nickel strips, etc.) in lithium batteries.

Severity separator

Due to the difference in specific gravity between the copper and aluminum mixture, can be filtered using a gravity separator specific. The front end of the separator is copper particles with heavier specific gravity. And the rear end of the separator is aluminum particles with lighter specific gravity. For this, you can get more benefits from lithium battery.

How to recycle lithium battery to get more profit?

If you plan to recycle lithium batteries, which can help you make more profits, Our lithium battery recycling line is an ideal choice for you. It can help you get graphite powder, cobalt acid, lithium, aluminum and copper, etc. quickly and easily. So, What is the design of lithium battery recycling production line? (Tips: The lithium batteries processed at the plant are all discharged)

Double axis crusher

If you want to recycle lithium batteries, The first step is to crush them into small pieces.. First you must shred lithium battery into small pieces to facilitate subsequent shredding. After crushing them, one piece measures 10 cm long and 4 cm wide.

Hammer mill

The finer the lithium battery powder, the better the quality of the final product. Therefore, A suitable shredder is necessary for recycling lithium batteries. In this case, he hammer mill It is an excellent option for you. And we recommend you buy two hammer mills for making lithium battery fine powder. After grinding twice, the length is 3-4 cm and the width is 2 cm.

Sorting screen

The screening machine In this step you can use a circular vibrating screen or a linear vibrating screen. Can help you filter out some of the metal from lithium battery waste.

Magnetic separation machine

The magnetic separation conveyor is equipped with a magnetic separation device which can separate magnetic materials (iron layers, nickel strips, etc.) in lithium batteries.

Severity separator

Due to the difference in specific gravity between the copper and aluminum mixture, can be filtered using a gravity separator specific. The front end of the separator is copper particles with heavier specific gravity. And the rear end of the separator is aluminum particles with lighter specific gravity. For this, you can get more benefits from lithium battery.

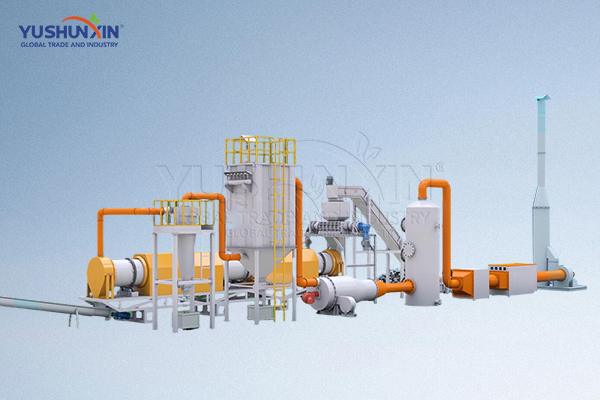

How to eliminate waste gas generated by recycling lithium batteries?

For the installation of a lithium battery recycling plant, there is an element you should pay attention to. This is the treatment of waste gas. To avoid environmental pollution, Removing waste gas from lithium batteries is essential. But, how to make exhaust gases harmless? We recommend you buy our spray tower, activated carbon adsorption box, oxygen with ultraviolet light and pulsed dust collector.

spray tower

Harmful gases are generated during the recycling of lithium batteries. How to use spray tower for recycling? The gas enters the tower through the lower entrance and moves upwards. After passing through the filler, the residual gas comes into full contact with the liquid phase and is absorbed, and then enter the next process through the upper dehydration layer, thus achieving the purpose of dust removal. The filtration air volume of the spray tower is 30.000 m³/h and the purification efficiency is ≥99%. Can effectively absorb harmful gases.

ultraviolet light oxygen

This equipment uses a specially designed high-energy, high-ozone ultraviolet beam to produce a cracking effect to eliminate smell to dust gas produced by recycled lithium batteries. And the air volume of UV photolysis treatment is 30.000 m³/h and the deodorization effect is 99%.

Activated carbon adsorption box

The harmful gas treated by the spray tower enters the activated carbon adsorption box. The adsorption capacity of activated carbon adsorbent surface is used to adsorb the pollutants in the exhaust gas on the surface of activated carbon, so that they are separated from the gas mixture. Activated carbon adsorption box is a dry exhaust gas treatment equipment, consisting of a box body and an adsorption unit filled in the box body. The filtration air volume of the activated carbon adsorption box is 30.000 m³/h.

Pulse dust collector

It can collect and discharge the dust and ultrafine powder (that is to say, the materials of the positive and negative electrodes of the battery) generated during the operation of the entire set of lithium battery recycling equipment under negative pressure.

How to eliminate waste gas generated by recycling lithium batteries?

For the installation of a lithium battery recycling plant, there is an element you should pay attention to. This is the treatment of waste gas. To avoid environmental pollution, Removing waste gas from lithium batteries is essential. But, how to make exhaust gases harmless? We recommend you buy our spray tower, activated carbon adsorption box, oxygen with ultraviolet light and pulsed dust collector.

What is the cost of a lithium battery recycling production line?

Lithium battery recycling production line price is an item you need to focus on. So, What is the budget for a lithium battery recycling line? In general, This production system requires between $35 000 y $150 000 (Reference price). But it's not fixed, because it is closely related to the types of materials and the capacity. The fewer types of materials and the lower capacity, the lower the cost. If you want to get a more accurate quote for the lithium battery disposal plant you need, you can contact us immediately. We will offer you a customized project design and corresponding quote.

What is the cost of a lithium battery recycling production line?

Lithium battery recycling production line price is an item you need to focus on. So, What is the budget for a lithium battery recycling line? In general, This production system requires between $35 000 y $150 000 (Reference price). But it's not fixed, because it is closely related to the types of materials and the capacity. The fewer types of materials and the lower capacity, the lower the cost. If you want to get a more accurate quote for the lithium battery disposal plant you need, you can contact us immediately. We will offer you a customized project design and corresponding quote.

In addition to the lithium battery recycling plant, There are also many other solutions for the Electronic waste recycling, such as solar panel recycling line, circuit board disposal plant, tire pyrolysis plant, etc. Welcome to contact us for your own e-waste recycling business plans.

In addition to the lithium battery recycling plant, There are also many other solutions for the Electronic waste recycling, such as solar panel recycling line, circuit board disposal plant, tire pyrolysis plant, etc. Welcome to contact us for your own e-waste recycling business plans.

ContentHide