Are you looking for solar panel disposal solutions?? Want to know what solar panel business plans are available to you?? Do you want to buy quality machines for your solar panel production line?? You can find answers at SUNRISE. SUNRISE, as a professional e-waste recycling equipment factory, has advanced technology and years of experience in manufacturing solar panel recycling machines. Plus quality solar panel removal equipment, We can also provide you with various business plans for solar panel removal. Besides, if you have any requirement, you can contact us to customize it. We will do our best to help you start solar panel recycling without any hassle!!

Are you looking for solar panel disposal solutions?? Want to know what solar panel business plans are available to you?? Do you want to buy quality machines for your solar panel production line?? You can find answers at SUNRISE. SUNRISE, as a professional e-waste recycling equipment factory, has advanced technology and years of experience in manufacturing solar panel recycling machines. Plus quality solar panel removal equipment, We can also provide you with various business plans for solar panel removal. Besides, if you have any requirement, you can contact us to customize it. We will do our best to help you start solar panel recycling without any hassle!!

Las 2 best solutions to recycle solar panels

In general, Most solar panel manufacturers prefer to recycle solar panels in two ways: physical and chemical methods. Therefore, to satisfy the different requirements of our customers, We specially design physical type solar panel disposal lines and chemical type solar panel recycling plants separately.

Physical type solar panel layout line design

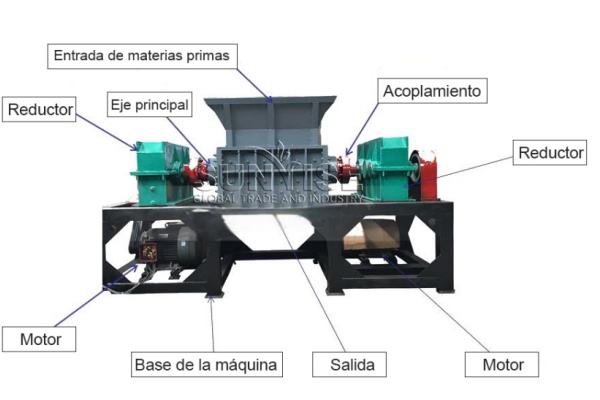

Physical type solar panel processing line is a simple process to recycle solar panels. You only need a few recycling machines and it can help you finish solar panel disposal. Includes frame extraction machine, deglazing equipment, double axis crusher, hammer mill, Vibratory screen, gravity separator and electrostatic separator.

Chemical type solar panel recycling plant technology

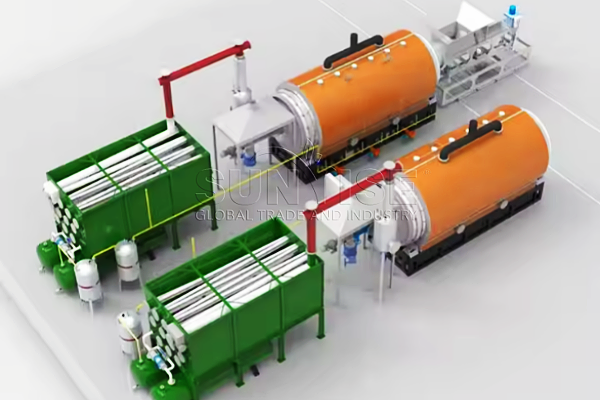

When you want to select another method to recycle solar panels, You can opt for the removal of chemical type solar panels. Then, because the process is more complicated, more solar panel processing machines needed.

In general, a complete solar panel chemical recycling line contains a pyrolysis oven, an air packaging machine, a buffer tank, a multi-stage coil condenser, A water sealant, A vibratory screen, a color sorter, a conveyor belt and a dust collector with bag filter. You can choose them to design your own solar panel recycling plan according to your needs..

Las 2 best solutions to recycle solar panels

In general, Most solar panel manufacturers prefer to recycle solar panels in two ways: physical and chemical methods. Therefore, to satisfy the different requirements of our customers, We specially design physical type solar panel disposal lines and chemical type solar panel recycling plants separately.

Physical type solar panel layout line design

Physical type solar panel processing line is a simple process to recycle solar panels. You only need a few recycling machines and it can help you finish solar panel disposal. Includes frame extraction machine, deglazing equipment, double axis crusher, hammer mill, Vibratory screen, gravity separator and electrostatic separator.

Chemical type solar panel recycling plant technology

When you want to select another method to recycle solar panels, You can opt for the removal of chemical type solar panels. Then, because the process is more complicated, more solar panel processing machines needed.

In general, a complete solar panel chemical recycling line contains a pyrolysis oven, an air packaging machine, a buffer tank, a multi-stage coil condenser, A water sealant, A vibratory screen, a color sorter, a conveyor belt and a dust collector with bag filter. You can choose them to design your own solar panel recycling plan according to your needs..

How to recycle solar panels by using the physical method?

If you plan to recycle solar panels on a lower budget, Our physical type solar panel removal line is an ideal choice for you. Can help you recycle solar panels quickly and easily. So, What is the design of physical type solar panel disposal line?

How to recycle solar panels by using the physical method?

If you plan to recycle solar panels on a lower budget, Our physical type solar panel removal line is an ideal choice for you. Can help you recycle solar panels quickly and easily. So, What is the design of physical type solar panel disposal line?

What machine can dispose of photovoltaic panels with chemical method?

Then, When preparing to dispose of photovoltaic panels with the chemical method, There are some machines needed in the solar panel recycling production line.

pyrolysis oven

The solar panels can be inserted directly into the pyrolysis oven, which heats photovoltaic panels in a high-temperature, oxygen-free environment to a temperature of 600 °C.

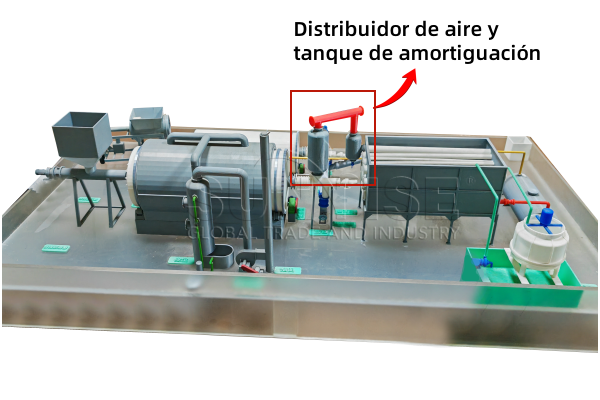

Air distributor and buffer tank

As a two-in-one device, gas separator and buffer tank play an auxiliary role. Once the pyrolysis of the photovoltaic panel is completed, The next step is the gas separator. This plays a gas storage role.. Then, Some of the gas will directly enter the buffer tank through the pipe. Due to the excessive impact force of the gas, can dampen the gas well.

Because the buffer tank is a closed tank, depends on the liquid inside to directly compress the air in the tank and play a cushioning function.

Multistage coil condenser

There are many pipes of different thicknesses and there is water in them. Water passes through these pipes to cool the room. Then, photovoltaic panels, after pyrolysis, They will become gas and then oil after passing through the condenser. That's why, We recommend connecting an oil tank at the back to temporarily store oil.

Water sealing system

This device can liquefy a small amount of gas that has not been liquefied in the condenser in the water seal, thus purifying the fuel gas. Besides, can also play a control role. The water inside can effectively prevent fire accidents caused by the furnace blowback. Finally, can also play a cushioning role, so that the fuel gas with unstable flow rate is discharged smoothly after passing through the water seal. This can better control the flow rate during afterburning and make the combustion more complete.. This can reduce the emission of pollutants and reduce safety risks.

Advice: You can recycle the gas that is not converted into oil as fuel for the pyrolysis furnace.

What machine can dispose of photovoltaic panels with chemical method?

Then, When preparing to dispose of photovoltaic panels with the chemical method, There are some machines needed in the solar panel recycling production line.

pyrolysis oven

The solar panels can be inserted directly into the pyrolysis oven, which heats photovoltaic panels in a high-temperature, oxygen-free environment to a temperature of 600 °C.

Air distributor and buffer tank

As a two-in-one device, gas separator and buffer tank play an auxiliary role. Once the pyrolysis of the photovoltaic panel is completed, The next step is the gas separator. This plays a gas storage role.. Then, Some of the gas will directly enter the buffer tank through the pipe. Due to the excessive impact force of the gas, can dampen the gas well.

Because the buffer tank is a closed tank, depends on the liquid inside to directly compress the air in the tank and play a cushioning function.

Multistage coil condenser

There are many pipes of different thicknesses and there is water in them. Water passes through these pipes to cool the room. Then, photovoltaic panels, after pyrolysis, They will become gas and then oil after passing through the condenser. That's why, We recommend connecting an oil tank at the back to temporarily store oil.

Water sealing system

This device can liquefy a small amount of gas that has not been liquefied in the condenser in the water seal, thus purifying the fuel gas. Besides, can also play a control role. The water inside can effectively prevent fire accidents caused by the furnace blowback. Finally, can also play a cushioning role, so that the fuel gas with unstable flow rate is discharged smoothly after passing through the water seal. This can better control the flow rate during afterburning and make the combustion more complete.. This can reduce the emission of pollutants and reduce safety risks.

Advice: You can recycle the gas that is not converted into oil as fuel for the pyrolysis furnace.

How to deal with the remaining remains of photovoltaic panels that have not been converted to gas?

In the pyrolysis oven, most photovoltaic panels are converted to gas. Additional treatment is necessary for the remaining slag that has not been converted to gas.

Tips: What is color sorter?

He color sorter is a device that uses photoelectric detection technology to automatically classify particles of different colors in granular materials based on differences in the optical properties of the materials.

How to deal with the remaining remains of photovoltaic panels that have not been converted to gas?

In the pyrolysis oven, most photovoltaic panels are converted to gas. Additional treatment is necessary for the remaining slag that has not been converted to gas.

Tips: What is color sorter?

He color sorter is a device that uses photoelectric detection technology to automatically classify particles of different colors in granular materials based on differences in the optical properties of the materials.

How to choose an area to install a solar panel recycling plant?

After purchasing the equipment, It is also necessary to prepare a suitable place to establish the solar panel recycling production line. In general, It is necessary to pay attention to two elements.

On the one hand, it is best to start preparation for solar panel disposal near the origin of the raw material. On the other hand, it is advisable to build solar panel disposal plants in places with convenient transportation. This way, it is easy to transport the material back to the factory and deliver the final products to customers.

Generally, you just need a site 500 a 1000㎡, solar panel recycling production line can help you complete the disposal of solar panels.

How to choose an area to install a solar panel recycling plant?

After purchasing the equipment, It is also necessary to prepare a suitable place to establish the solar panel recycling production line. In general, It is necessary to pay attention to two elements.

On the one hand, it is best to start preparation for solar panel disposal near the origin of the raw material. On the other hand, it is advisable to build solar panel disposal plants in places with convenient transportation. This way, it is easy to transport the material back to the factory and deliver the final products to customers.

Generally, you just need a site 500 a 1000㎡, solar panel recycling production line can help you complete the disposal of solar panels.

Las 2 best solar panel recycling investment solutions for your choice

When preparing to invest in a solar panel recycling project, You must take into account some factors, like the capacity, the machine and the budget. And if you are a beginner and don't know what scale of PV panel recycling equipment to buy, we will provide you with a full range of solutions for you to choose:

Sale of solution for the removal of solar panels 200 a 500 kg/h

If you plan recycle solar panels 500 kg/h, you can choose the physical method to dispose them. It only costs between $70 000 y $150 000. To do this, physical type solar panel removal line consists of frame removal machine, glass extraction equipment, A double axis crusher, a vibrating screening machine, a gravity separator and a high voltage electrostatic separator. This does not mean that you will use all the above equipment. We will choose the right equipment according to your needs to form a production line for you.

Solution for recycling project of photovoltaic panels 500-1000 kg/h

If you have enough budget and need to recycle on a large scale, This solution is the ideal option for you. You can not only choose the physical method, but also select a chemical type solar panel recycling solution. And this solution needs a pyrolysis oven, an air distributor and a buffer tank, a multi-stage coil condenser, a water sealing system and a pulse dust collector. You only need between $100,000 y $250,000.

But if you don't have enough budget and still want to use the chemical method to recycle solar panels, We can also provide you with a set of equipment that can meet the production and budget.

If your goal is to develop a photovoltaic panel processing center and you are at the stage of analyzing whether you can make an investment, You can also come and consult us. We will provide you with a personalized solution based on your current situation, from team selection, delivery to installation, site planning and after-sales service. Besides, we accept DDP, so you don't have to worry about customs clearance. after shipment, you just have to wait at home to receive the machine. It's not problematic at all.

Las 2 best solar panel recycling investment solutions for your choice

When preparing to invest in a solar panel recycling project, You must take into account some factors, like the capacity, the machine and the budget. And if you are a beginner and don't know what scale of PV panel recycling equipment to buy, we will provide you with a full range of solutions for you to choose:

Sale of solution for the removal of solar panels 200 a 500 kg/h

If you plan recycle solar panels 500 kg/h, you can choose the physical method to dispose them. It only costs between $70 000 y $150 000. To do this, physical type solar panel removal line consists of frame removal machine, glass extraction equipment, A double axis crusher, a vibrating screening machine, a gravity separator and a high voltage electrostatic separator. This does not mean that you will use all the above equipment. We will choose the right equipment according to your needs to form a production line for you.

Solution for recycling project of photovoltaic panels 500-1000 kg/h

If you have enough budget and need to recycle on a large scale, This solution is the ideal option for you. You can not only choose the physical method, but also select a chemical type solar panel recycling solution. And this solution needs a pyrolysis oven, an air distributor and a buffer tank, a multi-stage coil condenser, a water sealing system and a pulse dust collector. You only need between $100,000 y $250,000.

But if you don't have enough budget and still want to use the chemical method to recycle solar panels, We can also provide you with a set of equipment that can meet the production and budget.

If your goal is to develop a photovoltaic panel processing center and you are at the stage of analyzing whether you can make an investment, You can also come and consult us. We will provide you with a personalized solution based on your current situation, from team selection, delivery to installation, site planning and after-sales service. Besides, we accept DDP, so you don't have to worry about customs clearance. after shipment, you just have to wait at home to receive the machine. It's not problematic at all.

What final product can be recycled in a solar panel processing plant?

At a solar panel recycling processing plant, Various materials can be recovered and recycled to obtain final products. Key components that are typically recycled include:

The recycling process aims to minimize waste and recover as much material as possible for reuse., contributing to a more sustainable life cycle for solar technology.

What final product can be recycled in a solar panel processing plant?

At a solar panel recycling processing plant, Various materials can be recovered and recycled to obtain final products. Key components that are typically recycled include:

The recycling process aims to minimize waste and recover as much material as possible for reuse., contributing to a more sustainable life cycle for solar technology.

ContentHide

- Las 2 best solutions to recycle solar panels

- How to recycle solar panels by using the physical method?

- What machine can dispose of photovoltaic panels with chemical method?

- How to deal with the remaining remains of photovoltaic panels that have not been converted to gas?

- How to choose an area to install a solar panel recycling plant?

- Las 2 best solar panel recycling investment solutions for your choice

- What final product can be recycled in a solar panel processing plant?