Do you need a way to get rid of circuit plates? Are you trying to find a way to develop your electronic waste recycling business? But it has no previous experience in the recycling of circuit plates. Here, You can start with the elimination of circuit plates. In general, can help you process between 200 y 1000 kg of circuit plates per hour. And has low energy consumption characteristics, does not contaminate the air, highly automatic program, etc. Therefore, It is an ideal option for beginners who wish to establish a circuit plate recycling plant. So, How to start with the elimination of circuit plates? You can consider it from the following aspects:

Los 2 Best electronic waste recycling business plans for the elimination of waste circuit plates

There are two recycling plans for circuit plates for your choice: Circuit plate disassembly line and crushing and separation plant.

Circuit plate disassembly line

Are you looking for a plan to recycle electronic waste from circuit plates to disassemble them? Do you want to buy a circuit plate disassembly line for the installation of electronic waste recycling? If your answer is yes, We recommend that you buy this plant to disassemble circuit plates.

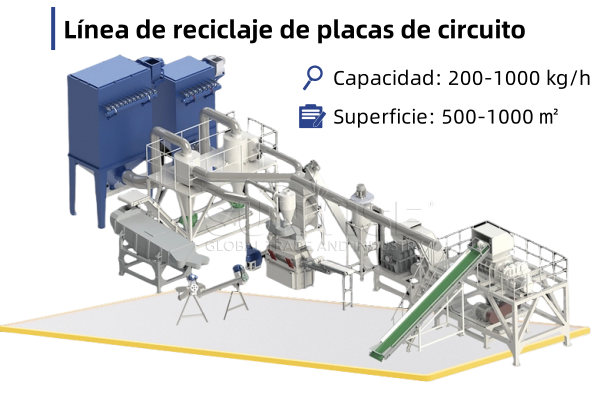

Crushing and separation plant of printed circuits

However, If you need a circuit plate elimination project with high commercial gains, The posterior processing of disassembled circuit plates to turn them into precious metals is their best option. Besides, Gains for the sale of precious metals are very high, So it is more beneficial for sale.

How to disassemble the circuit plate before separating precious metals?

It is necessary to disassemble the electronic components of the PCB, which is the most important step in the circuit plate recycling plant, since it can help the conservation of resources, the reuse of components and the elimination of hazardous environmental materials. So, How is the circuit plate disassembled?

Circuit plate disassembly machine

It is a device that is used to disassemble electronic components of waste circuit plates. Achieves the purpose of hot fusion and tin elimination heating the machine body (There is fire on the drum). You can also separate electronic components and welding of waste circuit circuit plates from circuit plates. More important, You can get copper materials of the dismantled motherboard, which increases the recycling rate of precious metals.

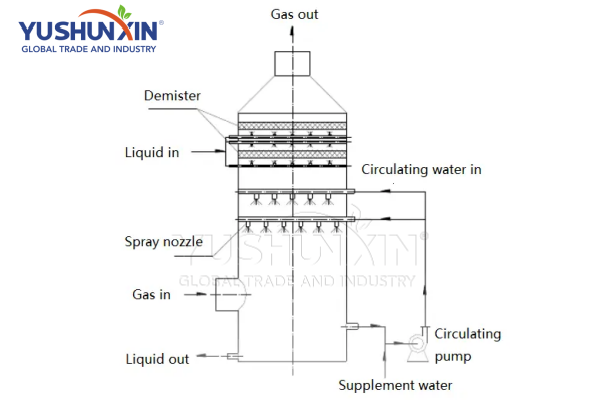

How to remove residual gases in the circuit plate disassembly process?

In the circuit plate disassembly process, dust and exhaust gases are generated. At the moment, The corresponding equipment is needed to solve this problem. The spray tower, Adsorption with activated carbon and plasma purification machine can solve this problem.

How to mount a recycling plant for suitable circuit plates for you?

If you want to make the disassembled circuit plate even more, In addition to the previous processes, You must also process them as follows:

Linear vibratory sieve (Particle size classification)

Severity separator (Particle density classification)

High voltage electrostatic separator (Driving separation)

How much does a recycling production line production line cost?

He Circuit recycling production cost usually vary according to capacity, The team, The configuration and many other factors. Here we will show the prices of the circuit plates removal plant 200-500 kg/h and the recycling line of circuit plates 500-1000 kg/h for reference.

200-500 kg/h

- Area: 500-1000㎡

- Reference

500-1000 kg/h

- Area: 600-1200㎡

- Reference

What can be recycled from a circuit plate?

Debido to the high value of Metals, Fiber and resin, There is no doubt that this recycling machine for waste PCB base, but also provides great economic benefits. But inappropriate storage or elimination of PCB can cause the release of harmful chemical substances such as mercury and lead, that can contaminate the natural environment and represent risks to human health. When recycling PCB, The negative environmental impact can be reduced, minimize the consumption of natural resources and reduce electronic waste, which contributes to a more sustainable future.

Debido to the high value of Metals, Fiber and resin, There is no doubt that this recycling machine for waste PCB base, but also provides great economic benefits. But inappropriate storage or elimination of PCB can cause the release of harmful chemical substances such as mercury and lead, that can contaminate the natural environment and represent risks to human health. When recycling PCB, The negative environmental impact can be reduced, minimize the consumption of natural resources and reduce electronic waste, which contributes to a more sustainable future.

Why choose the Yushunxin circuit plaque recycling project?

ContentHide