Si want to buy equipment for recycling and processing electronic waste. The electronic waste shredding equipment will be the one that best suits your needs. The electronic scrap separation equipment has strong crushing capacity. And can recycle and process electronic waste more effectively. This shredding and recycling method is very efficient and fast. Crushed metal particles can be processed and used again, which is not only true economic value. And it also contributes to some extent to environmental protection..

Why you should use e-waste shredders?

Electronic waste is the fastest growing solid waste in the world, and the issue of electronic waste recycling is one of the main global concerns. E-waste includes all types of discarded or used electronic equipment and electronic products. Some examples are discarded mobile phone batteries., solar panels, circuit boards and appliances,etc. Electronic waste usually contains various recyclable materials such as metals., plastics, glass and electronic components, and some also contain dangerous substances such as lead and mercury. The correct recycling and disposal of this electronic waste is essential for the protection of the environment, resource recovery and human health, as well as to comply with legal requirements regarding the environment.

When is it necessary to shred electronic waste during the recycling process?

E-waste shredders play a vital role in modern waste management and resource recycling. Its main function is to reduce the volume of waste through physical means and improve recycling efficiency.. So, When is the shredder usually used in the electronic waste recycling process??

Pretreatment before pyrolysis

Precious metal detection

Las 2 best e-waste shredders for sale

There are two shredders suitable for recycling electronic waste: a double shaft crusher and a hammer mill.

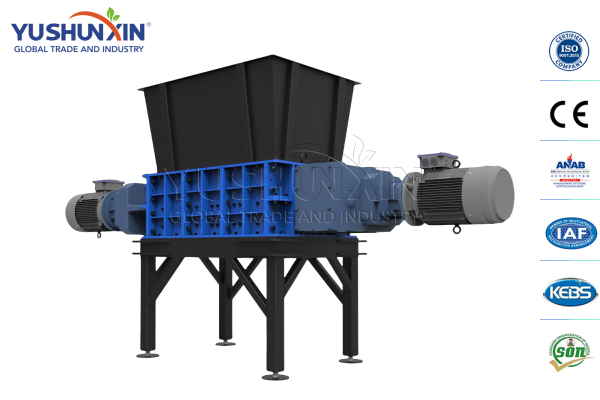

Double shaft shredder for electronic waste recycling

The double axis crusher It is a low-speed, high-torque knife roller machine that crushes materials into small pieces by two rotating shafts parallel to each other and covered with knives.. It is suitable for handling hard and large waste and garbage. The small crushed pieces are usually about 30-40 mm and size can be customized.

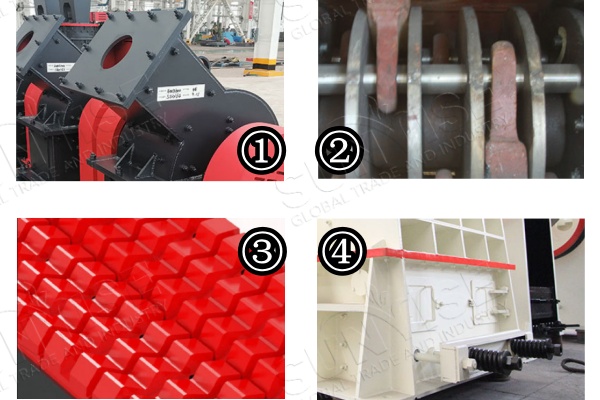

Hammer mill for electronic waste management

If you want to process the material even finer, We normally recommend installing a hammer mill after double shaft crusher. Rotary hammers and hook blades continuously hit the material to break it into smaller particles. The size of the crushed material is usually about 20 mm, although it can also be customized.

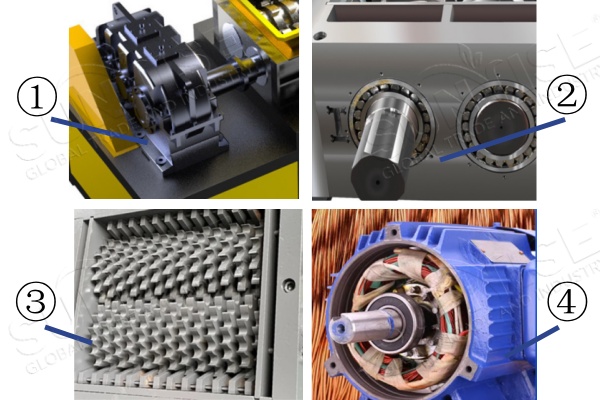

What is the design of e-waste shredding equipment?

Double axis crusher

Hammer crusher

How much do electronic waste shredders cost??

E-waste shredder price is also an item you should focus on. In general, according to the price of electronic waste shredder, we divide them into two parts:

The hammer mill is mainly used to further crush e-waste after primary processing to help separate metals and plastics.. And the double shaft shredder is generally used to handle large and hard e-waste. Therefore, when choosing a crusher, You should not only look at the price, but also for which materials it is suitable. If you want to get a more accurate quote on e-waste shredders, Contact us immediately using the contact form below!

Le-waste shredding equipment, are your pre-processing equipment in the recycling and disposal process of electronic waste. After crushing, can be finely sifted. Besides, we can offer you other e-waste processing equipment, as vibrating screen, specific gravity classifier, magnetic separator, inter alia. If you are interested, feel free to contact us.

ContentHide

- Why you should use e-waste shredders?

- When is it necessary to shred electronic waste during the recycling process?

- Las 2 best e-waste shredders for sale

- What is the design of e-waste shredding equipment?

- How much do electronic waste shredders cost??

- How to further process shredded e-waste to obtain more precious metals?

- Why choose our e-waste shredding equipment ?