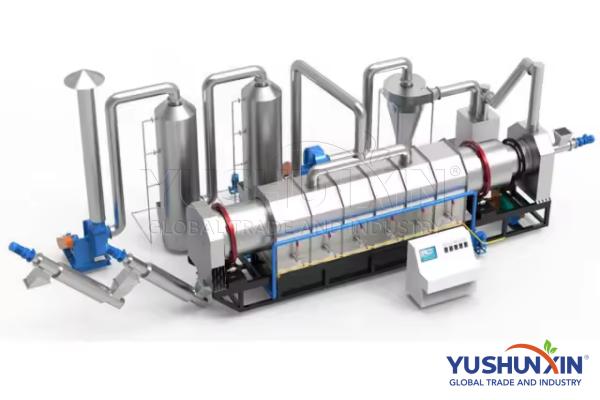

The solar panel pyrolysis machine is a profitable solution for the efficient management of waste solar panels. Through pyrolysis technology, The machine can take advantage of resources and treat solar waste panels. The final products, as metal, silicon, Glass and plastic, obtained by the machine can be applied in many fields. Currently, Pyrolysis teams of solar panels have become the option of many investors to Recycling of waste solar panels.

What types of solar panel pyrolysis machines should you choose?

To meet your recycling needs of solar and large -scale panels, Yushunxin offers a wide selection of solar panel pyrolysis machines. They can serve several recycling scales of waste solar panels, from 10 t/h until 50 t/h.

Discontinuous pyrolysis machine

This machine uses an intermittent production mode of "an oven per day". Each batch of raw materials undergoes a pyrolysis reaction for a specific time. Once the reaction stage is finished, The general operation of the machine goes to the cooling stage. Finally, by -products are downloaded and new materials are recharged for the next cycle. In general, Discontinuous type pyrolysis equipment includes a food system, a reactor, A condenser, a downloader and a waste gas treatment system.

Semi -nasy pyrolysis equipment

The advantages of semicontino pyrolysis equipment include greater flexibility in the processing of raw material and potentially lower operating costs compared to completely continuous systems. However, They may not achieve the same performance or efficiency as continuous systems. The choice between lots pyrolysis, semicontinua and continues depends on factors such as the type of raw material, the processing volume and the specific requirements of the application.

Continuous pyrolysis plant

The continuous pyrolysis plant offers large and highly automated solutions for solid waste. Currently, The ecological crisis caused by unsustainable solid waste recycling has attracted great attention, especially plastic, Oil sludge and tires. They are large in quantity and difficult to decompose in a harmless way. The appearance of continuous pyrolysis technology has solved these problems. With the mode of automated operation and strict emission control, The continuous pyrolysis machine has become the first option to recycle these solid waste.

| Pyrolysis Machine Type | Processing Capacity | Features |

| Batch pyrolysis machine | 100KG-20Ton per day/set | Hot sale pyrolysis products, suitable for most of the investors for its high efficiency and favorable prices |

| Semi-continuous pyrolysis machine | 10-20Ton per day/set | Cost-effective choice for investors who want higher automation degree middle scale pyrolysis machine |

| Fully continuous pyrolysis machine | 15-50Ton per day/set | High automation degree, PLC intelligent control, 24/7 hours running, suitable for big industrial waste recycling business investors |

Las 3 better price solutions for the recycling of solar panels by pyrolysis

In the case of a full solar panel pyrolysis plant to recycle solar panels and turn them into valuable materials, The cost is closely related to equipment design. Next, Some examples are offered for reference:

Although the general equipment of these three solutions is similar, We will adjust the equipment according to your real situation.

How to reduce the cost of solar pyrolysis waste panels?

Can we start a large -scale solar panel pyrolysis project at a lower cost? Of course. In addition to the types of equipment and capacity, The price of solar panel recycling is also related to the equipment used. That is to say, can reduce the cost by adopting a simpler process. For example, A system of 1000 kg/h consists of discontinuous type pyrolysis, condenser, residual gas treatment system, vibratory screening machine only needs between $20 000 y $40 000. If you want to obtain a precise price for the solar panel pyrolysis system you need, Welcome to contact us immediately. As a reliable manufacturer of Electronic waste recycling machines, Yushunxin will design the solutions according to their real requirements and conditions. Of course, including your budget.

What final product can be recycled after the pyrolysis of solar panels?

The pyrolysis of solar panels can generate several valuable by -products that can be recycled or reused. Solar panels are mainly composed of materials such as glass, Metals (like aluminum and silver), silicon and plastics, all of which can be recovered to some extent through the pyrolysis process.

4 Pyrolysis machine designs of solar panels with environmental shape

In the pyrolysis process of photovoltaic panels, There are some elements on which most solar panel administrators focus. In general, The most important thing when carrying out a recycling business of photovoltaic panels is the protection of the environment, especially we update the designs as follows.

WASTUAL GAS TREATMENT

For residual gas, We design the non -condensable gas to return to the oven for combustion. The large -volume induced shooting fan guarantees slight negative pressure in the oven to avoid disorganized combustion gases in the workshop. desulfurated by an alkaline solution in the atomization tower to ensure that the residual gas meets the emission standards.

Noise treatment design

The noise source comes mainly from the operation noise of equipment such as horizontal rotary crack ovens, Combustion Chamber Blowers, Induced shooting fans, Oil pumps, Water pumps, cooling towers, etc. For this, We use high quality silent equipment to guarantee stable operation and meet the noise standards.

wastewater recycling

Wastewater is mainly recycled water, and the amount of wastewater produced by the water seal is: 50 kg of wastewater for each 10 tons of raw materials processed. Because the amount is small and easy to process, After centralized treatment, The residual gases of the. The atomization tower is downloaded periodically. The wastewater of the atomization tower is recycled and not discharged.

Waste treatment

Waste residues mainly include crack oven and waste residues after fuel combustion in the combustion chamber. And the waste residue in the oven is black with thick smoke and metal impurities can be used as an additive for burning coal in energy. Or after its subsequent processing, It can be used as an industrial raw material. Combustion chamber waste can be used as auxiliary filling for construction materials (In the burning of coal, There are no waste when gas or oil is burned).

FAQ

LPyrolysis machine is efficient and environmental respectful. It is a good option to recycle solar panels. It is a profitable recycling business for you. We also provide other electronic waste recycling equipment, as Recycling machines for printed plates y Lithium battery recycling machines. We invite you to contact us to obtain your exclusive solution of electronic waste recycling equipment.