1000kg/h printed recycling machines

Ability – 1000kg/h

Precio – $20.000 – $30.000

Classification rate – 99%

Material – Q235b、stainless steel

Final product – copper powder、resins and fibers

Application – Electronic waste, metal, madera, paper, etc.

Global service

Service all day

Better guaranteed prices

Accept all credit cards

Ein the digital age, los Electronic waste have become one of the main environmental problems of global concern, and scrap circuit boards are a key component of this. Sincerely, we launch the 1000kg/h printed plate recycling machines. This type of machine is not only ecological and efficient, but also can perfectly convert waste into valuable resources, giving you economic benefits.

A. Scope of application of 1000kg/h printed board recycling machines

Specialized in processing various circuit boards, copper clad laminates, scrap mobile phone plates and others Electronic waste. The equipment shreds and separates the waste circuit boards and recovers the metal from the waste circuit boards. The remaining non-metallic materials can be converted into polymeric material products through specific processes. Can achieve the purpose of energy saving, emissions reduction and resource recycling.

Of the. What is the operation process of 1000kg/h printed plate recycling machines??

First, remove the electronic components connected to the circuit board. And collect electronic components.

Break electronic circuit boards by primary shredding and secondary shredding. The circuit board is processed into a mixture of metal powder and resin fiber powder.

Use vibrating separator to initially separate resin fiber powder and metal powder.

Use a gravity separator to separate the mixture again.

Then, electrostatic separator is used to further separate resin fiber powder. and metal powder to complete the separation and classification of metals in electronic waste.

Three. Composition of 1000kg/h printed plate recycling machines

Circuit plate disassembly machine

The tin of the circuit plate is loosen and melted by electrical heating and roller rotation. And this separates the electronic components from the circuit board.

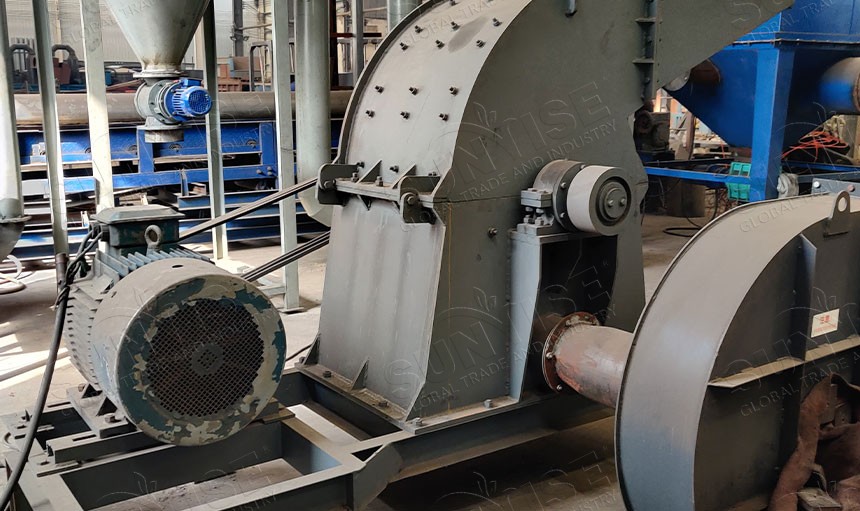

Double axis crusher

By rotating two shines of blades with blades, First the circuit plate is crushed.

Hammer fluoncer

The internal structure is a hook blade and a hammer head. Under the high speed rotation of the main axis, the material is crushed twice.

Severity separator

The screening is done according to the weight of the different materials.

Electrostatic separator

Under a high voltage magnetic field, The materials are shown based on whether they are conductors.

Four. Advantages of 1000kg/h printed plate recycling machines

Processing capacity up to 1000 kg/h significantly improves the speed and scale effect of resource recovery.

With exquisite craftsmanship and scientific recycling processes, gold recycling rate, plata, copper, iron and other metals has been greatly improved, allowing you to take full advantage of all the values of scrap circuit boards.

Reduce pollutant emissions throughout the entire process to ensure that production activities not only meet economic profit needs, but they are also ecological and respectful of the environment.

The efficient and environmentally friendly circuit board recycling equipment 1000 kg/h not only helps companies obtain enormous economic benefits, but also promotes sustainable social development.

Cinco. Price of 1000kg/h printed plate recycling machines

The price of the equipment varies depending on the model, accessories and materials. Price range is: $20.000 – $30.000. Detailed quotes can be obtained by contacting us.

En summary, circuit board recycling equipment 1000 kg/h is a ideal option to process large scale electronic waste. Besides, we offer electronic board recycling equipment 500 kg/h, Lithium battery recycling machines of 2000 kg/h y solar panel recycling equipment 10 tons/day. If you are interested, Please contact us.