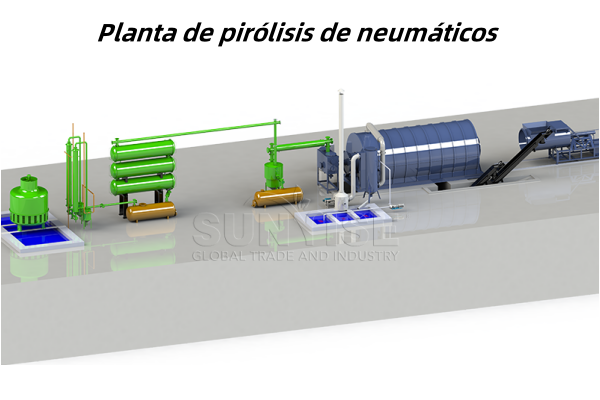

A pneumatic pyrolysis plant is a specialized industrial installation designed to recycle used and discarded tires through the pyrolysis process. This environment -respecting technology addresses the growing concern for tire waste by turning them into valuable by -products, as pyrolysis oil, Black coal and steel wire. The pyrolysis process implies heating tires in the absence of oxygen, Decomposing them in smaller molecules and resulting in the production of renewable energy sources and raw materials that can be used in several industries. When implementing pneumatic pyrolysis plants, We can significantly reduce waste waste, decrease environmental pollution and contribute to a circular economy by converting waste into useful products.

What is the pyrolysis process of tires?

If you plan to perform a pneumatic pyrolysis that allows you to obtain more profits, Our pneumatic pyrolysis plant is the ideal option for you. Can help you get high quality oil easily and quickly. The cracking equation of used tires is the following:

(-CH2-CH2-)n → [C+H2+CH4+C2H6+C3Hg+C4Hio+CsH12+…+C1H24+…C20H42+..

(Use: CSH12 ~ CH24 is a gasoline fraction, C12H26 ~ C20H42 is a diesel fraction and C20 is a heavy oil).

After understanding the principles of the pyrolysis of used tires, Let's take a look at the real functioning of the used tire pyrolysis plant.

Pneumatic pretreatment

If the pyrolysis machine is equipped with A tire crusher, First processes tires in smaller pieces that meet the food requirements.

Feed of pieces of processed tires

The pieces of tires that meet the specifications are transported to the pyrolysis reactor through a food system, Like a conveyor belt, a hydraulic feeder or an automatic screw feeder.

Pyrolysis

Heat the hot air from the combustion chamber. When the temperature reaches 180 ℃, Petroleum gas begins to form. Then, Heavy oil is collected in the sludge tank, while the lighter oil gas rises and flows to the condensation system.

Condensation

In the condenser, Petroleum gas is liquefy to become pyrolysis oil, which is then stored in the oil tank. Non -condensable fuel gas is recycled to the combustion chamber to sustain the heating process.

Offal

Hot escape gases enter the dusted system after cooling. Various dusted treatments (Washing with water, spray, Adsorption with ceramic ring and adsorption with activated carbon) They guarantee that emissions comply with environmental standards.

Waste download

Once the pyrolysis reaction is finished, The water cooling system cools the reactor to 50-80 °C. At this point, Coal black can be downloaded safely.

Solution 100% Recycling in pneumatic pyrolysis plant

Every year, 1.500 Millions of used non -biodegradable tires threaten the ecological environment. The pneumatic pyrolysis machine provides a sustainable solution for the use of resources and waste reduction. When subjecting the used tires at high temperatures in an environment without oxygen, We can transform them into several valuable products:

Solution 100% Recycling in pneumatic pyrolysis plant

Every year, 1.500 Millions of used non -biodegradable tires threaten the ecological environment. The pneumatic pyrolysis machine provides a sustainable solution for the use of resources and waste reduction. When subjecting the used tires at high temperatures in an environment without oxygen, We can transform them into several valuable products:

Product distribution analysis and raw material options for pyrolysis

| Raw Material | Details | Fuel Oil | Steel Wire | Carbon Black | Combustible Gas |

| Tires | Truck Tires | 45%-50% | 15%-20% | 30% | 5%-10% |

| Car Tires | 40%-45% | 10%-15% | 40% | 5%-10% | |

| Bicycle/motorcycle Tires | 30%-35% | 5%-10% | 10% | 5%-10% | |

| Rubber | Rubber Cable | 25%-35% | |||

| Shoes Sole | 25%-35% | ||||

| Mixed Sole | 20%-30% | ||||

| Sneakers | 20%-30% | ||||

| Waste Fiber Carpet | 30% | ||||

| PMMA | 40% |

Product distribution analysis and raw material options for pyrolysis

| Raw Material | Details | Fuel Oil | Steel Wire | Carbon Black | Combustible Gas |

| Tires | Truck Tires | 45%-50% | 15%-20% | 30% | 5%-10% |

| Car Tires | 40%-45% | 10%-15% | 40% | 5%-10% | |

| Bicycle/motorcycle Tires | 30%-35% | 5%-10% | 10% | 5%-10% | |

| Rubber | Rubber Cable | 25%-35% | |||

| Shoes Sole | 25%-35% | ||||

| Mixed Sole | 20%-30% | ||||

| Sneakers | 20%-30% | ||||

| Waste Fiber Carpet | 30% | ||||

| PMMA | 40% |

What is the price of your recycling of used tires?

The cost is an element in which most people focus when selecting a pyrolysis plan of used tires. But the price of the pneumatic pyrolysis plant is generally not fixed. Is related to many factors, especially the type of tires and machine configuration. Next, You can know the detailed cost of the pneumatic pyrolysis system.

From the previous introduction, We can learn that the tire pyrolysis line configuration is simple. In addition to the pyrolysis machine, It only contains an air distributor and a damping tank, A multiple stages coil condenser, A water sealant, A conveyor belt, etc. In general terms, The simpler the equipment configuration, minor will be the cost and less will be the occupation of space. Therefore, This pneumatic pyrolysis plan only needs an investment of $ 50,000- $ 100,000 and a factory area of 500-5,000㎡.

What is the price of your recycling of used tires?

The cost is an element in which most people focus when selecting a pyrolysis plan of used tires. But the price of the pneumatic pyrolysis plant is generally not fixed. Is related to many factors, especially the type of tires and machine configuration. Next, You can know the detailed cost of the pneumatic pyrolysis system.

From the previous introduction, We can learn that the tire pyrolysis line configuration is simple. In addition to the pyrolysis machine, It only contains an air distributor and a damping tank, A multiple stages coil condenser, A water sealant, A conveyor belt, etc. In general terms, The simpler the equipment configuration, minor will be the cost and less will be the occupation of space. Therefore, This pneumatic pyrolysis plan only needs an investment of $ 50,000- $ 100,000 and a factory area of 500-5,000㎡.

How to reduce the cost of its pneumatic pyrolysis plant?

In summary, If you want to set up a pyrolysis line of tires at a minor cost, You can act from the following aspects:

Why do they focus on the problem of eliminating used tires?

Why do they focus on the problem of eliminating used tires?

Non -biodegradable and environmental pollution

Used tires are difficult to break down and may take decades or centuries in decomposing. Your persistence can cause soil and water pollution and release unpleasant odors, which negatively affects ecosystems.

Challenges of volumes and elimination

Used tires are bulky and occupy a lot of space, which makes its elimination a great challenge. Often, They simply stacked in open areas, which generates problems of land use and antisthetic garbage.

Challenges of volumes and elimination

Used tires are bulky and occupy a lot of space, which makes its elimination a great challenge. Often, They simply stacked in open areas, which generates problems of land use and antisthetic garbage.

Fire danger

The flammability of tires is a safety risk. Once they come on, They are difficult to turn off and produce large amounts of harmful smoke. This article presents security risks for nearby regions.

Resource value

Used tires are mainly composed of synthetic and black carbon rubber. Therefore, Despite being difficult to degrade, They can be processed and reused to obtain other products, rubber dust, fuel or construction materials.

Why choose Sunrise as a partner to recycle tires?

Pre -sale support

- Free professional technical consultation on products

- Materials tests with specialized bilingual test report

- Personalized technical solutions according to customer requirements

Sales support

- Free design of the equipment disposition based on the conditions of the client site

- Real -time updates on the manufacturing and delivery status of the product

- Customer acceptance in the factory to verify the products before delivery

After sales support

- Professional orientation in situ for installation, start -up and training

- Technical consultation and periodic monitoring of customers

- Free software update service for the control system

Large -scale manufacturing factory

- Factory area 26 000 m2 and office space 2000 M2

- Quick manufacturing capabilities and fast delivery deadlines

- Factory direct prices help you save on your budget

ContentHide