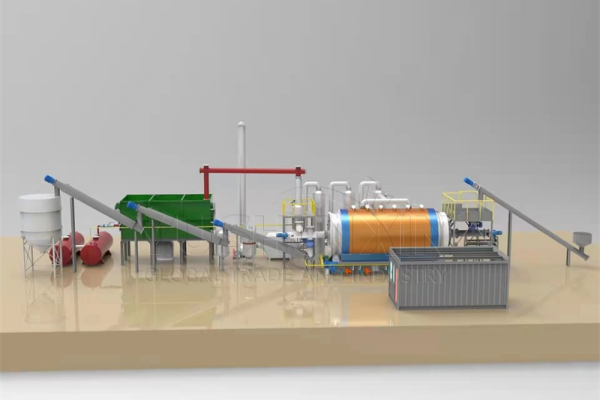

The plastic pyrolysis plant is specifically designed to achieve a plastic recycling of the 100 %. This pyrolysis machine plastic can convert plastic waste into pyrolysis oil and other by -products. World plastic production and consumption have increased every year. If properly eliminated, will cause a serious waste of plastic resources and environmental pollution. Therefore, follow us to obtain a pyrolysis solution that can achieve a circular plastic recycling.

Why choose plastic recycling according to viability analysis?

There are many ways to treat plastic, So why would you choose to recycle it? There are four reasons:

What is the plastic pyrolysis process?

Pretreatment and food

It must process raw materials in different sizes for food. Different feeding sizes for reference:

- 1

Plastic waste pyrolysis machine mounted on skates: The feed diameter is lower than 600 mm. Plastic feed is done manually.

- 2

Lot pyrolysis plant: The food diameter is lower than 1200 mm. Plastic feed is done manually.

- 3

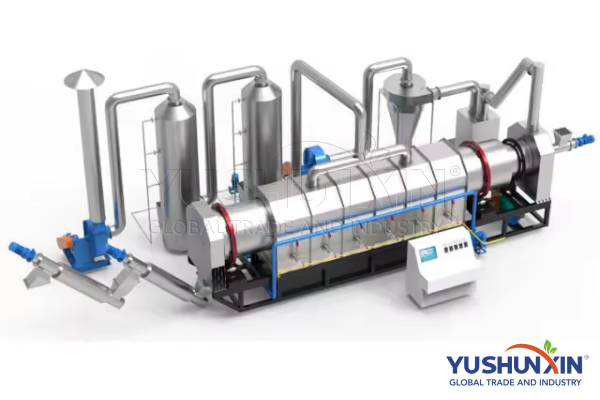

Continuous pyrolysis plant: The food diameter is lower than 20 mm. The plastic feeds by a screw feeder.

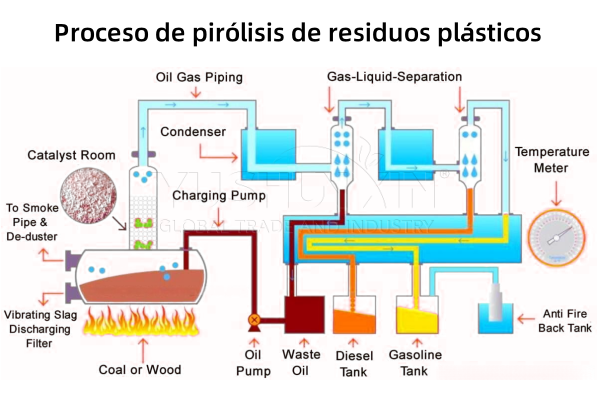

Plastic catalysis pyrolysis

Heat the main oven. When the temperature reaches 180 Celsius degrees, diesel begins to be generated. Temperatures between 280 y 350 Celsius degrees, There is a significant amount of diesel. After diesel enters the catalytic tower, experience a reaction with the catalyst. This step mitigates problems related to wax deposition and liquefaction. At the same time, It contributes to improving the quality of plastic pyrolysis oil.

Plastic pyrolysis oil collection

Oil gas enters the collector and heavy particles of oil gas will liquefy and fall into the heavy oil tank. And light oil gas will be liquefied through the capacitor and will be reserved in the fuel tank.

Recycling of combustible gases and solid waste

Non -liquefiable oil gas will be desulfurated and cleaned on the hydraulic label and then recycled in the combustion room as a heat source. And solid waste will be downloaded by labor downloaders (Mounted on skates) or water cooling.

Recycling of emission gases

When heating the reactor, The escape gases cool first in the smoke condenser. After, They go to a high -tech exhaust gas treatment system (Washing with water, Water spray, Adsorption with ceramic ring and adsorption with activated carbon). Finally, Downloaded exhaust gases meet European emission standards.

Are all plastics suitable for pyrolysis?

If plastic pyrolysis is available, You must keep in mind that not all plastics can pirolize. What plastics are suitable for recycling and which do not?

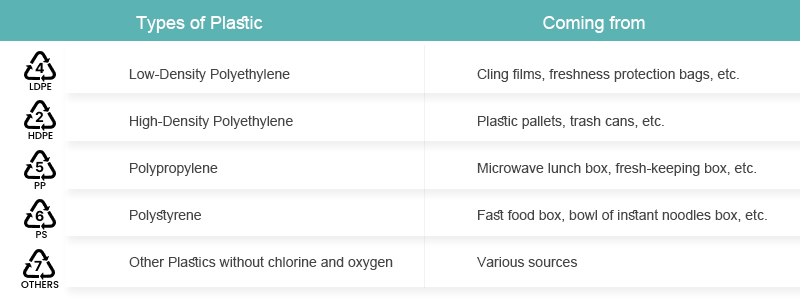

Acceptable types of plastic

PP polyolephine plastic wastes, PE and PS represented the 92% Of the total plastic products (28% PP, 46% LDPE Y HDPE, y 18% PS).

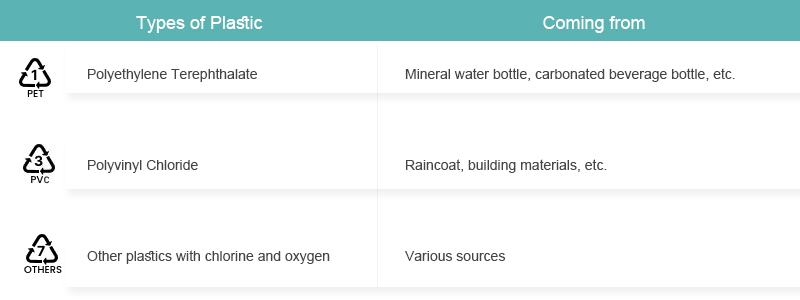

Non -acceptable types of plastic

Non -acceptable types of plastics mainly include chlorine and oxygen. During the pyrolysis process and post-pyolism, These two substances are risks to machines, air quality and safety.

What are the applications of plastic pyrolysis products?

Why do we recommend the Sunrise plastic pyrolysis plant?

Plastic pyrolysis plants play a crucial role in prolonging the useful life of plastics and combating plastic contamination. This approach presents new opportunities for the sustainable development of the plastic industry. Let's join the plastic recycling and we contribute to a more sustainable and responsible future with the environment.

ContentHide