For those looking to maximize their profits with lithium battery recycling, The best solution is to process used batteries to obtain high purity recyclable materials.. For small and medium scale recycling projects, a lithium battery recycling line 500 kg/h It is an excellent option. This line can process a large volume of used lithium batteries from factories or collection centers.. Besides, the recovered materials, like lithium, cobalt, nickel and graphite, They have a high purity, making it easy to reuse, transportation and marketing.

Who needs lithium battery recycling plant 500 kg/h?

When you want to know if this lithium battery recycling line 500 kg/h is right for you, It is advisable to consider three aspects: ability, final products and costs.

What to do with lithium batteries before separating them?

For the recycling of metals and high-quality black masses, the treatment of lithium batteries is essential. Before separation, Lithium batteries may need to be processed using the steps below.:

Crush lithium batteries

To increase the specific surface area and facilitate complete subsequent pyrolysis, need to open the lithium battery shell and crush the core into small pieces under nitrogen atmosphere. To do this, we recommend a single shaft shredder. This machine is equipped with a hydraulic push plate for force feeding, that crushes the material into flakes of 2 a 4 cm.

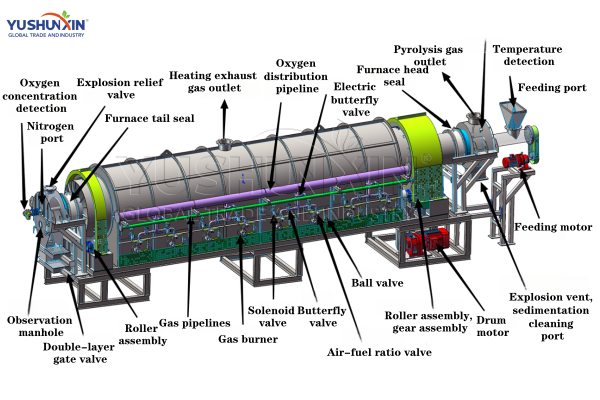

High temperature pyrolysis of lithium battery fragments

Additional processing is required to remove organic components from the crushed materials. It will be necessary to carry out pyrolysis at medium-high temperature of the battery raw materials to eliminate organic components such as the electrolyte., release paper and PVDF binder. In this process, It is recommended to use a carbonization oven with external heating, since it can reach temperatures of 400-600 °C in an oxygen-free environment. The final product is carbon black free of organic matter., such as separator and electrolyte. Its main components are black powder, copper and aluminum sheets, and fragments of steel casing.

What equipment is usually used after pretreatment of lithium batteries?

How many areas does the lithium battery disposal plant cover? 500 kg/h?

In addition to team selection, The factory area is another aspect that must be taken into account. Therefore, How many areas does the lithium battery disposal plant cover? 500 kg/h?

A lithium battery treatment plant with a capacity of 500 kg/h usually requires between 800 y 1200 m² of space to operate efficiently. This area includes areas for unloading, trituration, separation, dust collection and storage of finished product. If a completely closed workshop is added, safety zones and space for the circulation of forklifts, The total area required can reach between 1500 y 2000 m². On the whole, This distribution guarantees a smooth flow of materials, stable production and safe handling of discarded lithium batteries.

Are there other designs for the configuration of a lithium battery recycling plant? 500 kg/h?

Of course. Our clients have obtained benefits thanks to them. For example, In India there are lithium battery disposal lines with a capacity of 500 kg/h, lithium battery recycling plants, etc.

Besides, There are also recycling plans for lithium batteries with other capacities, like a lithium battery recycling line 1000 kg/h to Mexico, the purchase of a lithium battery disposal plant with a cost of 250.000 dollars in India, etc. Contact us now for your personalized e-waste recycling plan!!

ContentHide

- Lityum batareyali qayta ishlash zavodiga muhtoj 500 kg / h?

- Lityum bilan nima qilish kerak, ularni ajratishdan oldin nima qilish kerak?

- Lityum batareyasini oldindan tayyorlaganidan keyin odatda qaysi jihozlardan foydalaniladi?

- Lityum batareyasi bilan qancha joy ajratiladi? 500 kg / h?

- Lityum batareyali qayta ishlash zavodining konfiguratsiyasi uchun boshqa dizaynlar mavjudmi? 500 kg / h?