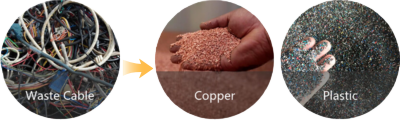

Thanks to its high copper content, waste cables are ideal for recycling. This not only benefits the recovery of this metallic resource, but also allows for greater profits. Is it possible to recycle copper cables in a simpler and more economical way?? Of course! Transforming discarded cables into pure copper granules. To do this, YUSHUNXIN offers a wide range of copper cable recycling machines. These machines allow you to complete cable recycling quickly and efficiently..

How to prepare waste cables for later recycling?

Before starting the copper and plastic separation process, Scrap cables require proper pretreatment. Using a wire stripping machine is the most efficient way to remove the outer insulating layer, exposing clean copper conductors. This step significantly improves recycling efficiency and ensures higher metal purity in subsequent separation stages..

For thin cables (<10 mm)

For processing small diameter cables, the most efficient option is to use a roller or blade wire stripper. These models are designed for precision cutting and allow quick removal of the insulating layer without damaging the copper core.. They are suitable for household cables, communication cables and electronic waste cables. Their compact structure and adjustable cutting depth make them ideal for small recycling plants or laboratories that require high peeling precision..

For thick cables (10-150 mm)

Thick cables require heavy-duty stripping machines with powerful motors and multiple cutting blades. These machines can easily process large, shielded cables with tough insulation layers.. Cutting depth and blade spacing can be adjusted to suit different diameters, ensuring clean separation of copper without deformation.

Heavy duty models are especially recommended for industrial recycling centers processing large volumes of power cables or underground cables with stable and continuous production demand.

How to recycle copper and plastic from waste cables?

If you want to get more benefits from scrap cables, recycling copper and plastic is an ideal option. But how do you quickly turn waste cables into marketable copper and plastic?? Generally, are required 5 steps: trituration, air separation, vibratory screening and electrostatic separation.

Advice: If required, you can add a magnetic separator to the conveyor belt that connects these two crushers. This will allow impurities to be removed previously., thus improving the final quality of copper and plastic.

How much does it cost to recycle copper cable??

The total investment for a complete copper cable recycling line usually ranges between 10 000 and the 150 000 dollars, depending on production capacity, automation level and configuration. Several factors influence both the cost of recycling and the final value of copper..

How to eliminate dust generated by recycling copper cables?

During recycling of copper cables, A large amount of fine dust is generated during crushing and separation. Installing an efficient dust collection system helps recover more copper and maintain a clean work environment. To do this, We recommend you purchase our pulse dust collector. Because?

In addition to our copper cable recycling plan, We can also offer you various machines for recycling electronic waste, as lithium battery recycling lines y solar panel treatment plans. You can also choose the pyrolysis method for recycling photovoltaic panels. Contact us today for your own e-waste recycling plan.