Best, its tire project involves the recycling industry and is attracting international investment. Tourism is the pillar of the local industry, and the national environmental protection requirements for this sector are very strict. So, How to effectively manage waste tires? He 10 April of 2025, A customer from Fiji asked us about the tire pyrolysis project. He told us that his waste tire recycling project usually generates 15 tons of waste tires per day. To do this, we recommend a batch pyrolysis plant.

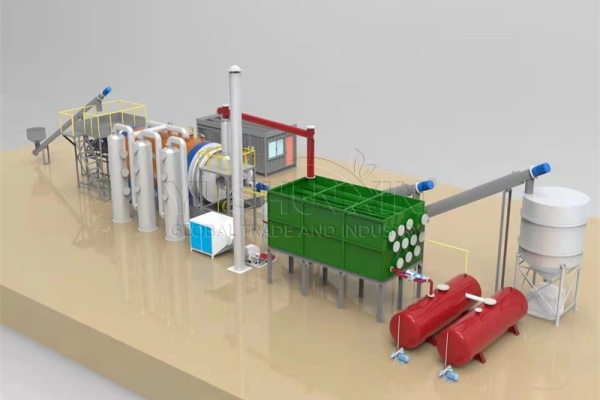

Which pyrolysis plant is suitable for recycling used tires from 15 t/d?

This Fijian client wanted to start a small to medium sized tire pyrolysis plant in Fiji, with great intention and potential for expansion. According to your budget, we recommend a batch pyrolysis plant.

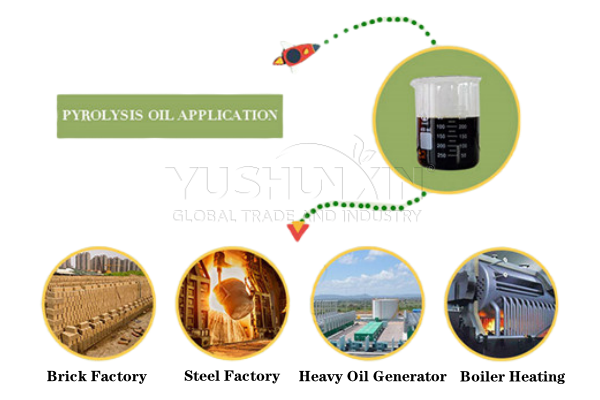

What are the versatile applications of tire pyrolysis products?

Normally, Waste tire pyrolysis plants use thermochemical reactions to decompose waste tires into pyrolysis oil (liquid), carbon black or steel wire (solid) and synthesis gas (gas). To do this, this client from Fiji was prepared to use them and generate more income. So, How to convert them into valuable resources and achieve 100% recycling?

What is the price of a used tire pyrolysis project? 15 t/d a Fiji?

Our Fijian clients recently invested in a used tire pyrolysis line of 15 TPD. The total cost of the project was approximately $320,000, that covered the main reactor, the cooling system, gas purification and auxiliary equipment. The price was within the usual range of $180,000 a $400,000 for this capacity.

Client compared semi-continuous and fully continuous solutions. Initially, considered a manual line to reduce the initial cost. However, after calculating labor costs, realized that a more automated system would reduce operating costs in the long term. Finally, opted for a semi-continuous line with partial automation, thus achieving a balance between investment and efficiency.

What is the land requirement for a used tire pyrolysis project? 15 t/d?

This customer from Fiji installed his plant on a plot of 2500 m², ideal for waste tire pyrolysis line 15 t/d. This space allowed us to have a safe production area, tire storage and separate areas for fuel and carbon black storage. In practice, a land of 2000 a 3000 m² is enough for this type of project. Initially, the client wanted a smaller plot to save costs. However, after our engineers provided you with a layout plan, realized that a reduced space would slow down the flow of materials and increase risks. With a more organized design, reduced construction costs and improved safety.

The above details our communication with the client regarding the solution for a waste tire pyrolysis project. 15 t/d en Fiyi. Besides, we have others electronic waste recycling plans, like a solar panel recycling plant, a Lithium battery elimination line, and waste plastic pyrolysis project, etc.