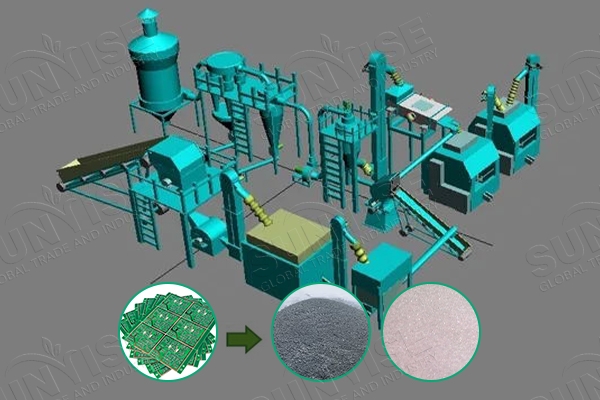

Electronic scrap separation equipment

Ability – 100 kg/h-5 t/h

Precio – $700 – $7.000

Classification rate – 99%

Material – Q235b,stainless steel

Warranty – 1 year

Application – Electronic waste, Metals, madera, plastic, etc.

Global service

Service all day

Better guaranteed prices

Accept all credit cards

En the recycling process of Electronic waste. After being crushed by a crusher, It is usually necessary to equip an electronic junk separation equipment. This team can classify fast and efficiently useful non -ferrous metals In electronic waste. So that these electronic waste can effectively recycle, thus providing economic benefits.

A. 6 Popular Classification Teams by Electronic Waste Vibration

Linear vibratory screen

Summary: The linear vibratory screen is a type of electronic junk separation equipment with a linear movement trajectory.

Principle of operation: The engine serves as a source of vibration, which makes the material thrown on the screen and advance in a straight line to achieve the screening purpose.

Application: It is mainly used to screen materials with fine particles, Specific Specific Gravity and Low Hardness.

Summary:The circular vibratory screen is a type of electronic scrap separation equipment with circular movement trajectory.

Principle of operation: The eccentric block turns at high speed, which makes the material vibrate with a circular movement on the surface of the screen, And then the material that meets the particle size requirements is signed.

Application: It is mainly used to screen material with heavy specific gravity, Large particles and high hardness.

Summary: It is a device that screens materials based on differences in its specific gravity.

Principle of operation: Under the action of air flow, The particles with less density will be dragged by the air flow, thus achieving the purpose of detection.

Application: Mainly suitable for separation between metals and non -metals, Powder materials and granular materials.

Summary: It is a device that uses a strong magnetic field to achieve an effective separation of magnetic and non -magnetic particles in mixed materials.

Application: Can be used to filter iron (Fe), nickel (In) and cobalt (Co) In electronic waste.

Summary: An electrostatic separator is a device that uses a high voltage electric field to filter different materials through adsorption and repulsion.

Principle of operation: Under a high voltage magnetic field. It has an adsorption effect on conductive metals, thus achieving a shielding effect.

Application: Mainly suitable for metal and non -metallic mixtures, Plastic rubber mixtures, minerals, etc.

Summary: It is a detection equipment that uses the color difference of the material itself to automatically identify the color difference of the material and classify it automatically.

Application: Mainly suitable for electronic waste detection, plastics, glass, Metals, minerals, etc.

Of the. What are the advantages of the six types of electronic waste classification equipment?

This team occupies a small space, has high detection efficiency, Energy saving and noise reduction. It is easy to install, easy to operate and maintain.

The circular vibratory screen is easy to operate, easy to clean and maintain.

Its main material is q235b, that has good corrosion resistance. Efficient, necessary, Save energy and it is convenient.

The magnetic separator has high separation efficiency, Save energy, It is ecological, safe and can work continuously.

The electrostatic separator can perform a separation of high precision and the separation rate can reach the 99%.

The optical classifier machine has a rapid and high precision classification speed. It is highly adaptable and can adjust the classification strategy flexibly.

Three. Electronic scrap separation equipment price

There are many factors that influence the price and the different models of double axis destructive machines have different prices. The production range of this series of double axis crushers It is approximately 600-2000kg/h and the price ranges between $2.000 – $14.000.If you want to have a more detailed understanding, You can contact us to obtain the parameters.

- 1The price of the linear vibratory screening (100 kg/h) It is from $1000-$3000

- 2The price of the circular vibratory screen (150 kg/h) It is from $700-$3000

- 3

The price of specific gravity separator (500-10000 kg/h) It is from $3000-$8000

- 4

The price of the magnetic separator (1-5t/h) It is from $1000-$3000

- 5The price of electrostatic separator (100-300 kg/h) It is from $3000-$7000

- 6The price rank of the optical classifier machine (100-1000 kg/h) It is from $2000-$7000

Four. 3 reasons to choose us as its manufacturer of the electronic scrap sepaation equipment

We are professional manufacturers of electronic waste collection equipment

We are manufacturers of electronic waste collection equipment, produced and sold.

Technology is guaranteed

We have a rich experience in research and manufacturing. The electronic scrap sepaation equipment is made up of professional engineers and technicians.

Personalized services and comprehensive solutions

We provide personalized solutions of electronic waste treatment systems according to their real needs and site conditions. We also provide full planning of the production line.

Reliable quality and comprehensive service

Products strictly follow international quality standards to guarantee a long -term stable operation of the equipment and low maintenance costs. We offer a comprehensive service.

EThe electronic scrap separation equipment is efficient and saves energy. Besides, We offer teams like double axis crushers, Hammel mills y solar panels disassembly machines. We invite you to contact us for more details.